In highly corrosive environments—such as seawater cooling, chemical processing, and offshore oil and gas—traditional stainless steel may not offer sufficient durability. Selecting the right material for heat exchanger tubes in these conditions is crucial for ensuring long service life, process safety, and reduced maintenance costs.

This article explores two high-performance materials: Titanium and Nickel Alloy tubes, and when they are best suited for corrosion-resistant heat exchanger applications.

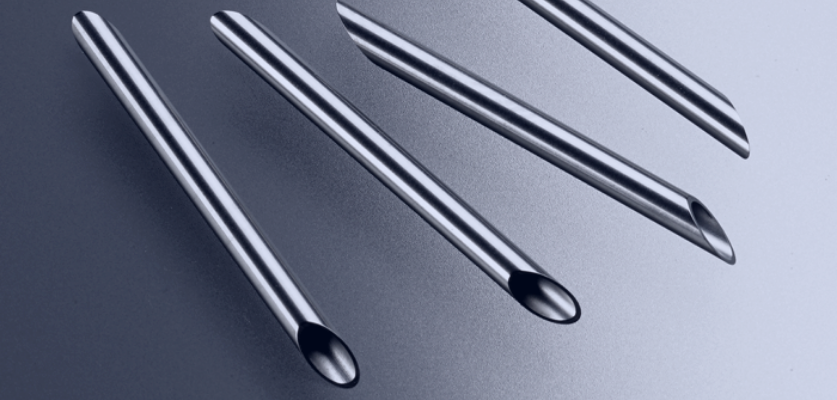

1. Titanium Heat Exchanger Tubes: Lightweight and Ocean-Ready

Titanium tubes are widely used in seawater-cooled heat exchangers due to their outstanding corrosion resistance, particularly against chloride ions and biofouling.

Key Benefits:

- Excellent resistance to saltwater, acids, and oxidizing environments

- Low density and high strength-to-weight ratio

- Long service life with minimal maintenance

Applications:

- Seawater-cooled condensers

- Desalination plants

- Marine heat exchangers

- Offshore platforms

Titanium Grade 2 and Grade 5 are commonly used. DLSS can supply titanium tubes as per ASTM B338 or ASME SB-338 standards upon request.

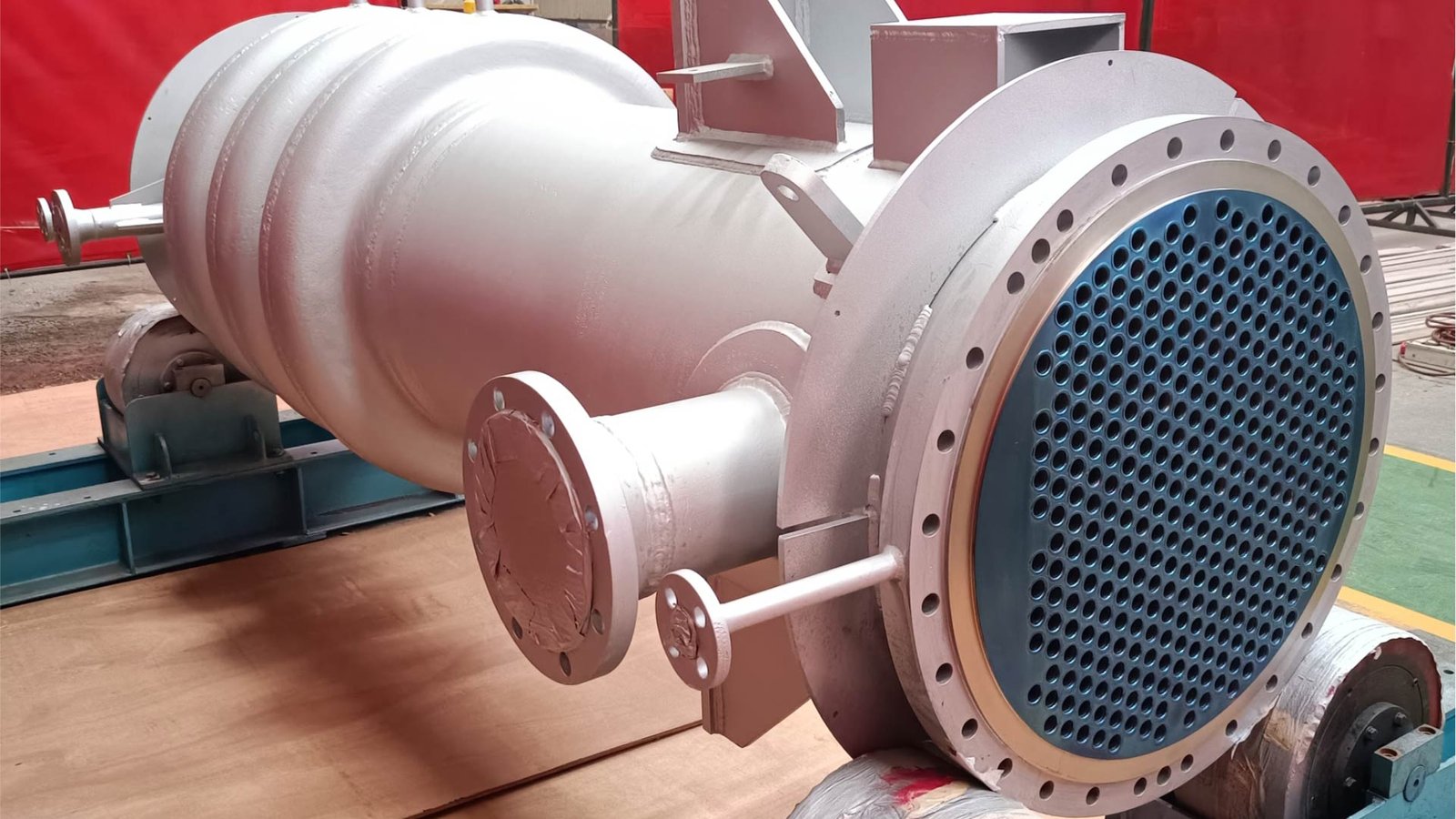

2. Nickel Alloy Heat Exchanger Tubes: Engineered for Extreme Conditions

Nickel-based alloys, such as Inconel (e.g., UNS N06625), Monel (e.g., UNS N04400), and Hastelloy (e.g., C-276), offer superior resistance to:

- High temperatures

- Oxidizing and reducing agents

- Sulfuric, hydrochloric, and nitric acids

These alloys are ideal for:

- Chemical processing

- Power plant condensers

- Acid regeneration units

- Heat recovery systems in petrochemical plants

At DLSS, we supply nickel alloy heat exchanger tubes with strict quality control, supported by mill test certificates and third-party inspections.

3. Why Corrosion Resistance Matters

When exposed to corrosive fluids or harsh environments, carbon steel or even standard stainless steel tubes may experience:

- Pitting or crevice corrosion

- Stress corrosion cracking

- Early wall thinning and leakage

Investing in titanium or nickel alloy tubes significantly reduces lifecycle costs, especially in continuous process industries where downtime is expensive.

4. DLSS Solutions for Harsh Environments

As an experienced manufacturer of industrial tubing, DLSS offers a range of corrosion-resistant solutions tailored for heat exchanger applications:

- Nickel alloys: Inconel 625, Monel 400, Hastelloy C276

- Titanium Grades 1, 2, and 5

- Duplex and Super Duplex (2205, 2507)

- Seamless tubes with customized lengths and surface finishes

- Compliance with ASTM, ASME, EN, and NORSOK standards

We also support special packaging, seaworthy protection, and third-party inspection services upon request.

Explore our corrosion-resistant tube solutions at www.dlsspipeline.com

Email us directly: info@dlsspipe.com