Meta Description:

Discover the key differences between electropolished (EP) and mechanically polished (MP) stainless steel tubes. Learn which surface finish is better for food, beverage, and pharmaceutical use in Latin America.

Introduction

In sanitary applications, cleanability is critical. Whether you’re building a milk pasteurizer in Brazil or a pharmaceutical system in Colombia, the inner surface of your stainless steel tubes directly affects hygiene, bacterial resistance, and compliance.

The two most common surface finishes used in sanitary stainless steel tubing are:

- Electropolished (EP)

- Mechanically Polished (MP)

But how do they compare? And which one is better for your project in Latin America?

What Is Mechanically Polished (MP) Tube?

Mechanically polished tubes are smoothed using abrasive polishing wheels or belts. This process removes surface imperfections and weld beads to achieve a consistent internal roughness.

- Typical surface roughness: Ra ≤ 0.8 µm

- Common finish: 180–240 grit

- Ideal for dairy, brewing, juice, and light pharmaceutical systems

Pros:

- Lower cost than electropolishing

- Available in a wide range of sizes and finishes

- Suitable for CIP systems with moderate hygiene requirements

What Is Electropolished (EP) Tube?

Electropolished tubes are treated in an acid electrolyte bath under electrical current, dissolving the top layer of steel. This results in a smoother, chromium-rich surface that is highly resistant to corrosion and microbe attachment.

- Typical surface roughness: Ra ≤ 0.4 µm

- Glossy, reflective interior finish

- Used in high-purity and ultra-hygienic systems, like pharmaceutical and biotech lines

Pros:

- Superior bacterial resistance

- Improved corrosion performance

- Easier to clean and sterilize

- Required by ASME BPE and FDA for injectable production

See comparison data on surface finishes from Alfa Laval

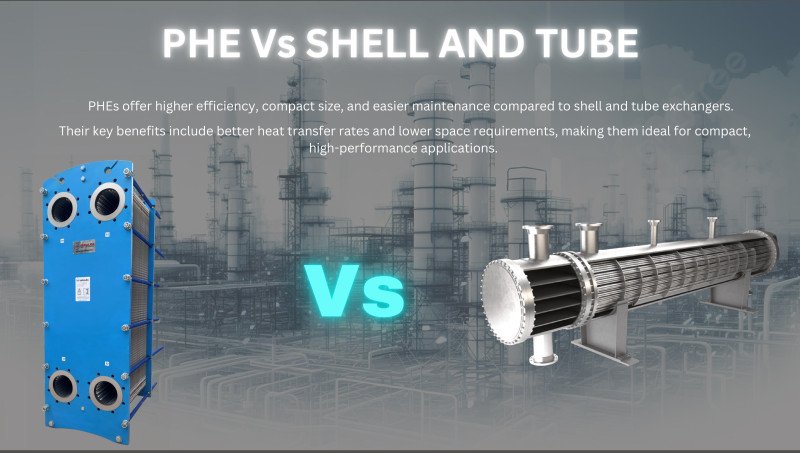

Comparison Table: EP vs MP

| Feature | Mechanically Polished (MP) | Electropolished (EP) |

|---|---|---|

| Ra (Surface Roughness) | ≤ 0.8 µm | ≤ 0.4 µm |

| Appearance (Interior) | Matte | Shiny, mirror-like |

| Bacterial Resistance | Good | Excellent |

| Compliance (BPE/FDA) | Optional | Often Required |

| Cost | Lower | Higher (20–40% more) |

| Common Industries | Food, Beverage | Pharma, Biotech |

| Cleaning Efficiency | Medium | High |

When Should You Choose EP Tubes?

Choose Electropolished Tubes if:

- You’re working on a pharmaceutical or injectable-grade project

- You need to comply with ASME BPE or FDA

- The process involves high-purity water or steam sterilization

- You want the longest possible tube lifecycle

Choose Mechanically Polished Tubes if:

- You’re in the food, dairy, brewing, or beverage sector

- You have standard CIP cleaning and no high-acid media

- Budget is limited, and Ra ≤ 0.8 µm is acceptable

DLSS Tube Finishing Capabilities

DLSS supplies both MP and EP tubes with full surface inspection and traceability.

| Specification | MP Tubes | EP Tubes |

|---|---|---|

| Finish Type | 180–240 grit | Acid bath + current removal |

| Surface Roughness | Ra ≤ 0.8 µm | Ra ≤ 0.4 µm |

| Size Range | 12.7 mm – 114.3 mm OD | 12.7 mm – 76.2 mm OD (standard EP) |

| Certification | ASTM A270, EN 10204 3.1 | ASTM A270 + ASME BPE + Ra Report |

| Testing | Ra Mapping, EC, Hydro, Visual | Ra Mapping, EC, Hydro, Micro-clean |

FAQs

Q1: Is EP finish required for food-grade applications?

Not always. For most food and beverage systems, mechanically polished tubes are sufficient. EP is usually required for high-purity pharmaceutical applications.

Q2: Can DLSS tubes be supplied with both MP and EP options?

Yes. We can supply MP only, MP + EP, or EP-only tubes depending on project needs.

Q3: Do you provide Ra test certificates with EP tubes?

Yes. All EP tubes include surface roughness testing with report mapping.

Conclusion

Both mechanically polished and electropolished tubes serve vital roles in Latin America’s sanitary industries. While MP tubes offer cost-effective hygiene for food and beverage plants, EP tubes provide superior cleanability and corrosion resistance for biotech and pharmaceutical systems.

DLSS offers tailored solutions with full documentation and surface inspection for both types of finishes.

Contact DLSS

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Need help selecting the right sanitary tube finish for your project? Contact our expert team for technical support and quotation today.