The heat transfer coefficient is one of the most important performance indicators of a finned tube. It determines how efficiently heat can be transferred between the tube-side and the air-side or shell-side medium. By understanding and optimizing the key factors that influence this coefficient, engineers can significantly improve overall heat exchanger efficiency.

For an overview of finned tube types, see Different Types of Finned Tubes and Their Applications. To explore how fin geometry impacts performance, check Spiral vs Extruded Finned Tubes: Which is Better for Your Project?.

Key Factors Affecting Heat Transfer Coefficient

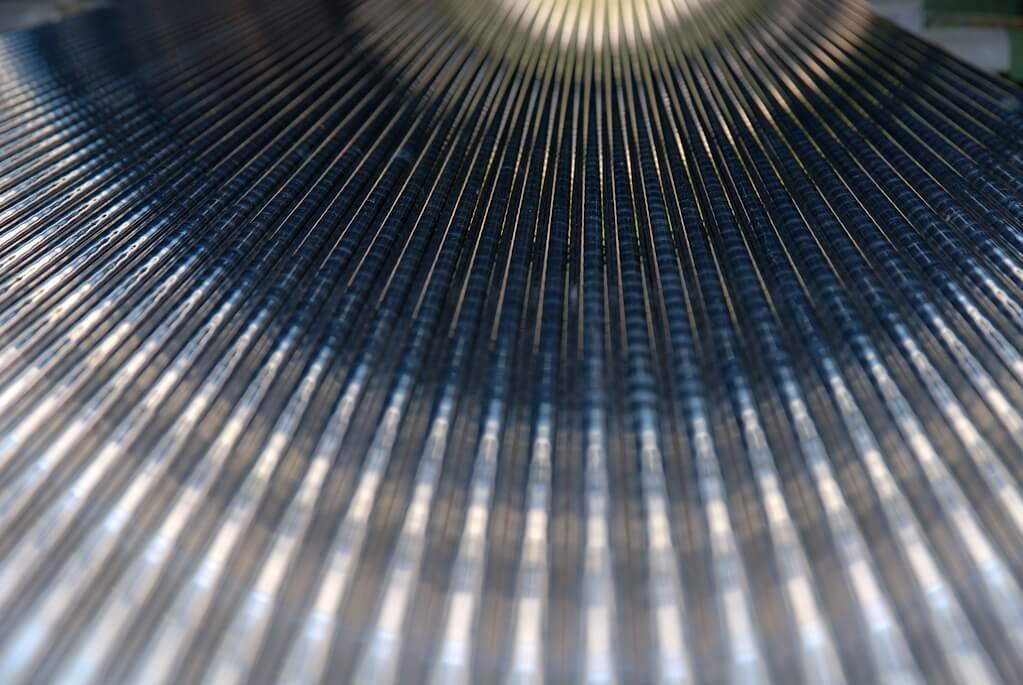

1. Fin Geometry

- Height – Taller fins provide more surface area but may increase airflow resistance.

- Pitch – Closer fin spacing increases area but can cause fouling.

2. Material Thermal Conductivity

- High-conductivity materials such as copper or aluminum improve heat transfer.

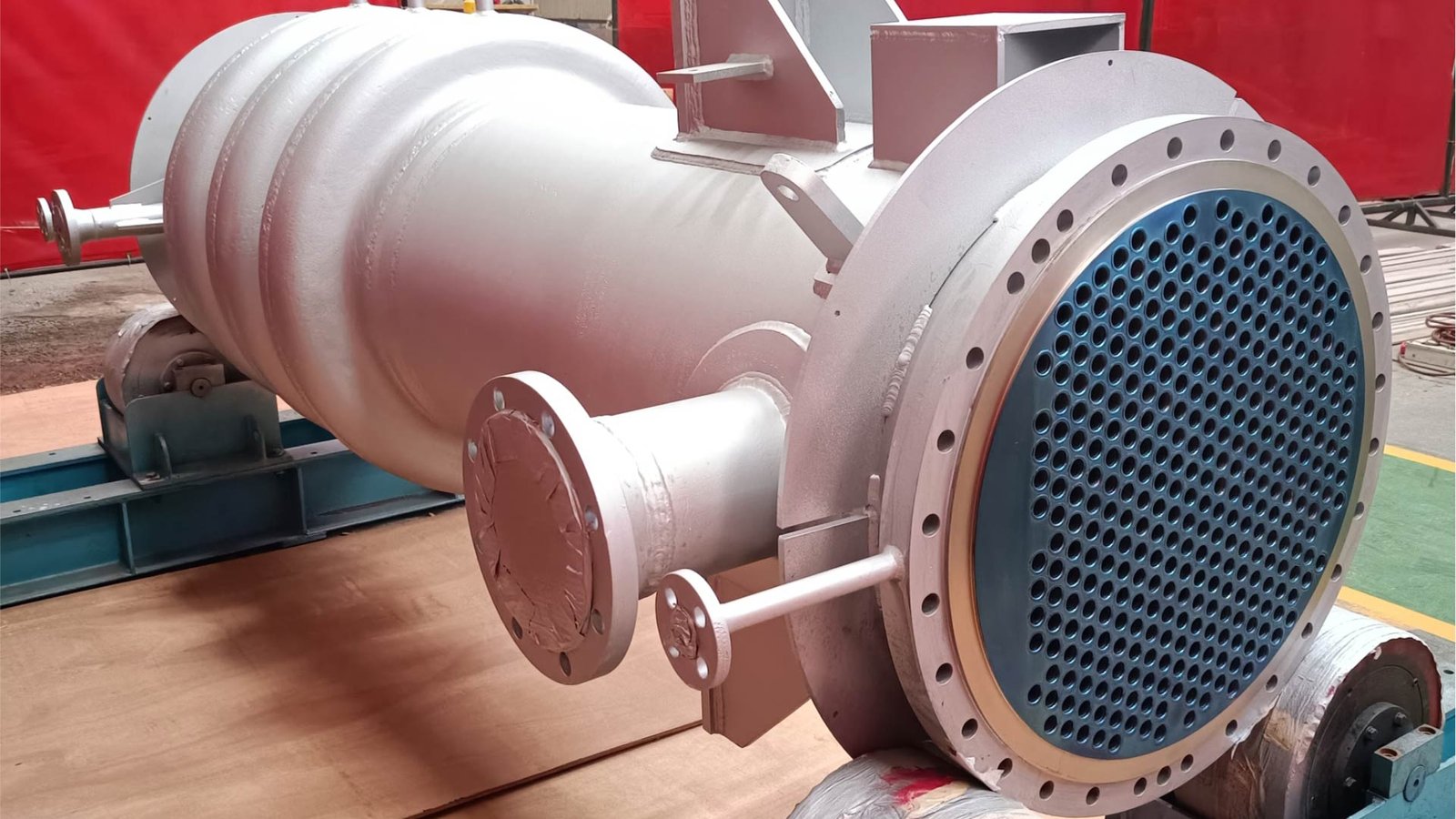

- For corrosive environments, Stainless Steel Finned Tubes may be the better choice.

3. Surface Treatment

- Coatings can improve corrosion resistance but may reduce thermal performance if too thick.

4. Operating Conditions

- Flow velocity, fluid temperature, and fouling factor directly impact coefficient values.

Optimization Strategies

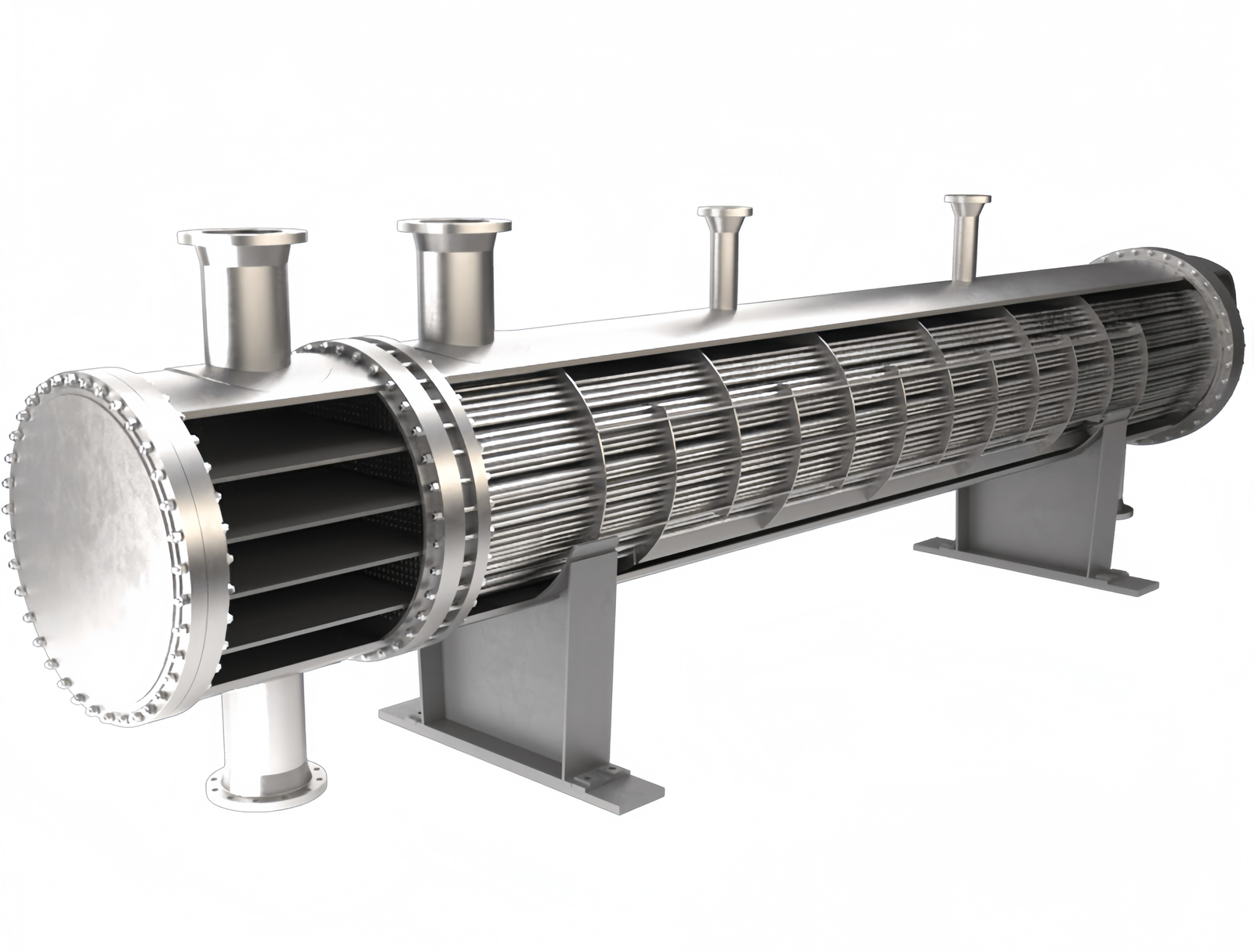

- Choose the Right Fin Type – For example, Low-Fin Tubes are ideal for compact systems, while spiral fins excel in high-airflow environments.

- Improve Air-Side Cleaning – Regular cleaning reduces fouling and maintains efficiency.

- Optimize Fin Pitch – Balances thermal performance and pressure drop.

Measuring and Monitoring

Continuous monitoring of outlet temperatures, pressure drop, and energy consumption can help detect performance deterioration early, allowing for timely maintenance and optimization.

Conclusion

Optimizing the finned tube heat transfer coefficient requires a combination of smart design, proper material selection, and proactive maintenance.

DLSS provides engineering support for fin geometry design, material selection, and performance testing to ensure your heat exchangers operate at peak efficiency.

Contact our technical team at www.dlsspipeline.com or email info@dlsspipe.com to discuss your project requirements and receive a tailored solution.