In the food and beverage (F&B) industry, heat exchangers play a vital role in processes such as pasteurization, sterilization, CIP cleaning, and temperature control in production lines. These systems must meet stringent hygiene requirements, resist corrosion, and maintain high thermal efficiency under continuous operation.

This article explores how heat exchangers are used in F&B, the importance of sanitary design, and why selecting the right stainless steel tubes is essential for food safety and system performance.

Heat Exchanger Applications in Food and Beverage

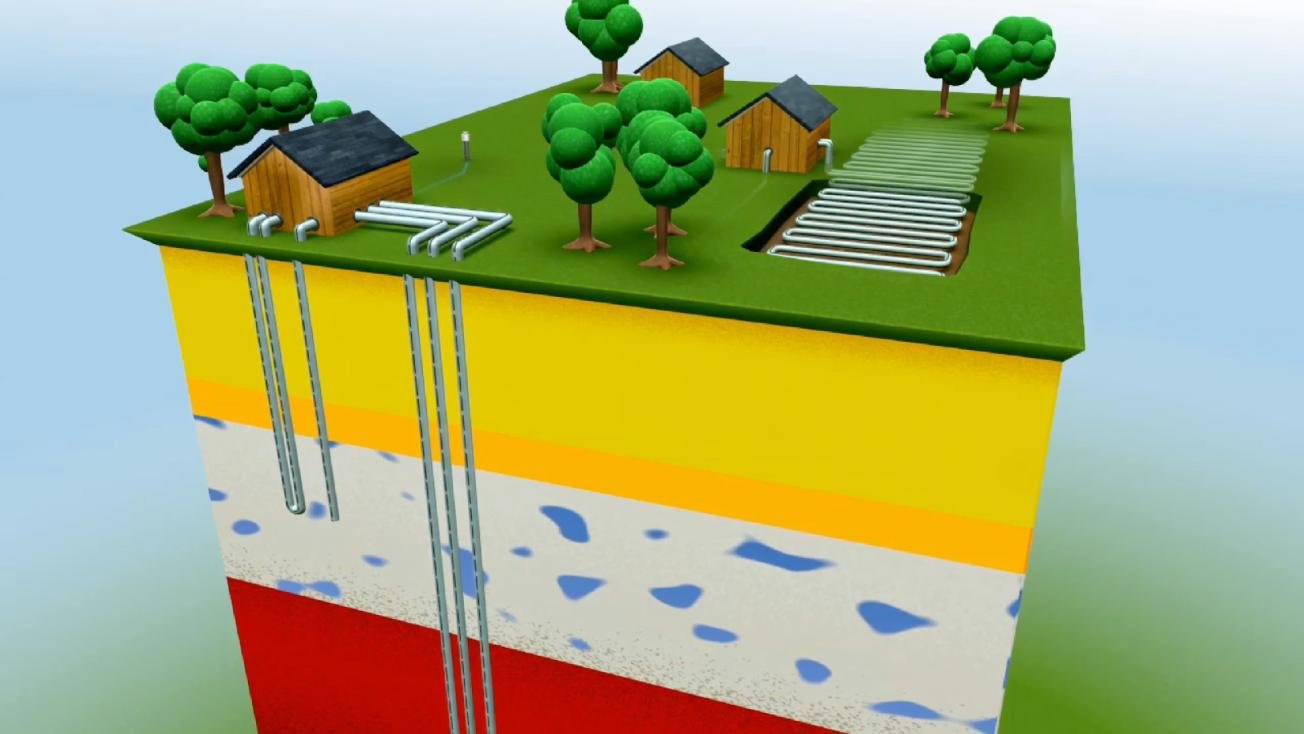

As outlined in Wikipedia – Heat Exchanger, heat exchangers facilitate thermal energy transfer between two fluids without mixing them. In F&B, this function supports:

- Milk pasteurization and UHT (ultra-high temperature) treatment

- Beverage and juice heating/cooling

- Steam-to-water heating for cleaning and sterilization

- CIP (Clean-in-Place) systems for pipe and tank cleaning

- Chocolate, yogurt, beer, and soup thermal processing

These applications demand reliable temperature control, easy-to-clean surfaces, and non-reactive materials to preserve product integrity.

Key Requirements for Food-Grade Heat Exchangers

| Requirement | Why It Matters |

|---|---|

| Corrosion Resistance | Avoids metal leaching and contamination |

| Sanitary Surface Finish | Prevents bacteria adhesion and residue buildup |

| Thermal Efficiency | Ensures consistent processing temperature and energy savings |

| Weld Seam Quality | Smooth, crevice-free to prevent microbial growth |

| Compliance with Standards | Must meet 3-A Sanitary, FDA, or EHEDG guidelines |

More info: Wikipedia – 3-A Sanitary Standards

Most Suitable Heat Exchanger Types in F&B

1. Plate Heat Exchangers (PHE)

- Compact and highly efficient

- Ideal for milk, beer, and juice

- Easy disassembly for cleaning

- Suitable for clean fluids with low particulate content

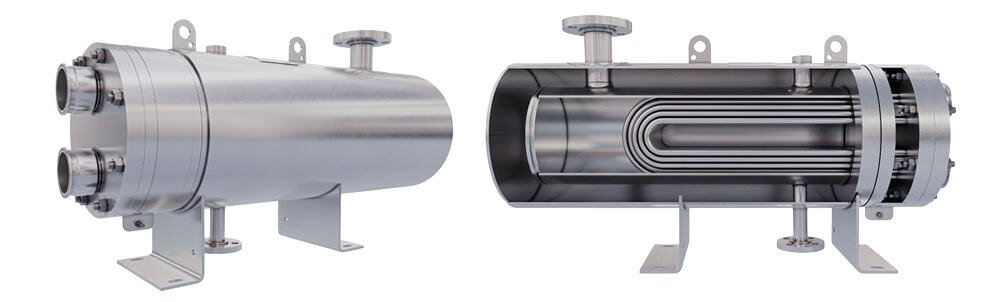

2. Shell-and-Tube Heat Exchangers

- Better for high-viscosity or particulate-laden fluids (e.g., soups, sauces)

- Easier to handle steam or thermal oil

- Can be cleaned using pigging or manual rod systems

- Available in double-tube sheet or multi-pass hygienic configurations

Why Stainless Steel Tubes Are Essential

Stainless steel is the industry standard for food-grade heat exchangers due to its:

- Resistance to corrosion, especially from acidic products (juice, dairy, fermentations)

- Smooth, non-porous surface, ideal for hygienic cleaning

- High durability under thermal cycling and pressure fluctuations

- Excellent weldability for leak-proof joints

Commonly used grades:

| Grade | Applications |

|---|---|

| 316L | Dairy, juice, meat processing, breweries |

| 304L | Clean water, CIP media, sugar solution |

| Duplex 2205 | Steam, brine, or high-salt content food production |

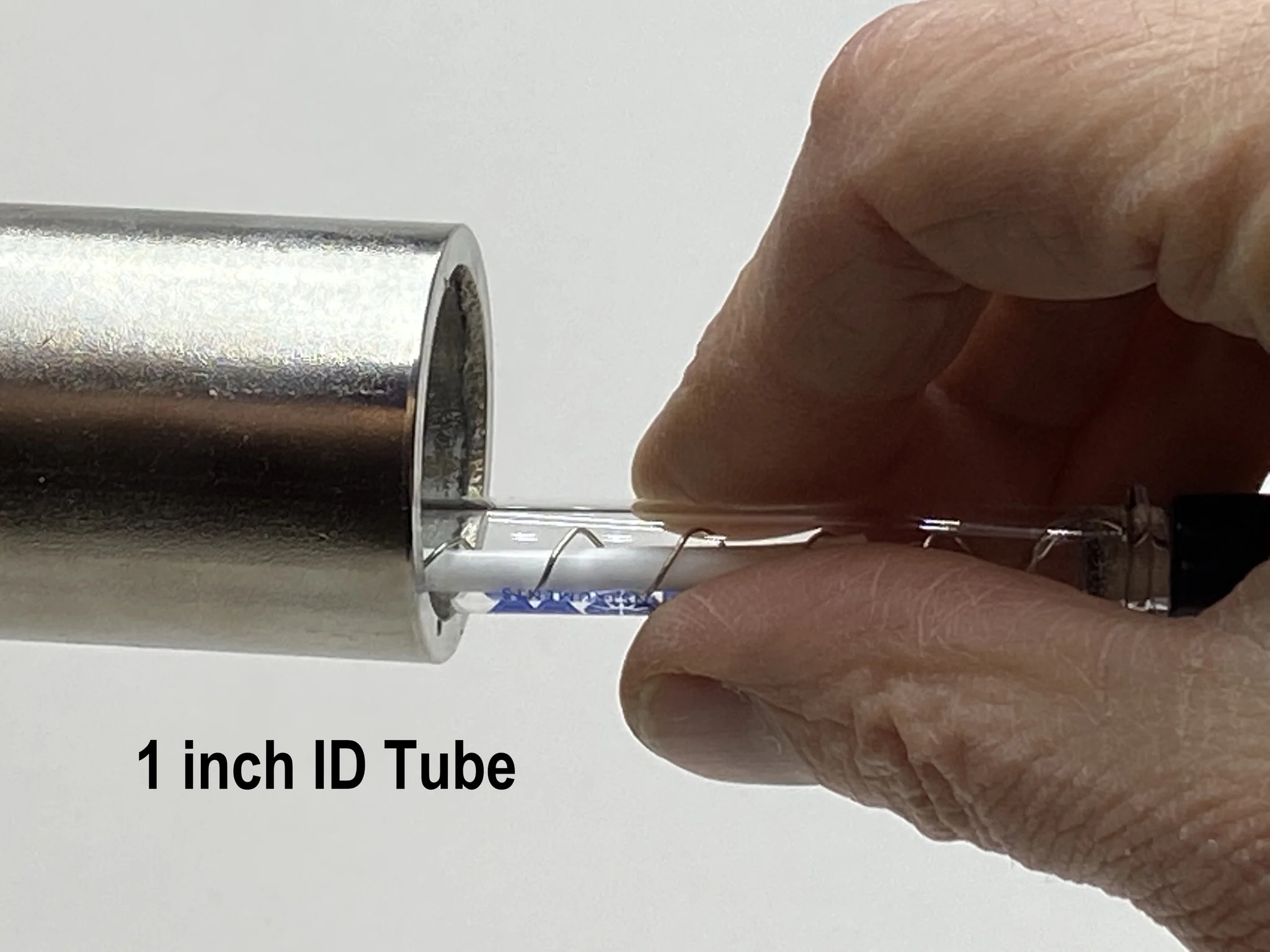

Polishing is critical: Ra ≤ 0.4 µm is typical for product-contact surfaces.

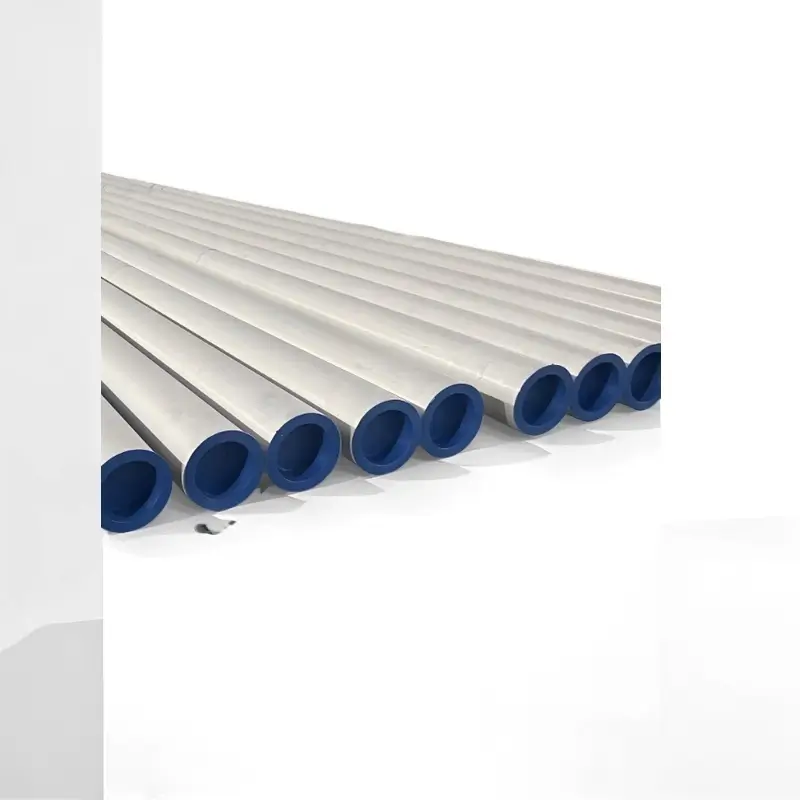

DLSS Tube Solutions for the F&B Industry

At DLSS, we manufacture precision stainless steel tubes tailored for food and beverage heat exchangers. Our tubes are:

- Made from certified 316L, 304L, and Duplex stainless steel

- Available with ID polishing for sanitary compliance

- U-bent or straight, per your exchanger design

- Supplied with EN 10204 3.1 certificates and optional 3-A marking

- Tested for hydro pressure, eddy current, and dimensional accuracy

See more: DLSS Heat Exchanger Tubes for Food Applications

Design Tips for Food-Grade Systems

- Use double-tube sheets to prevent cross-contamination between fluids

- Ensure all welds are ground and polished for sanitary approval

- Design for drainability and dead-leg elimination

- Choose CIP-compatible materials and tubing layouts

- Specify ASME BPE or EHEDG compliant tube systems when required

Frequently Asked Questions (FAQ)

Q1: What is the difference between 304L and 316L for food use?

316L contains molybdenum, making it more resistant to chlorides and acids—ideal for juice, cheese, and cleaning agents.

Q2: Are your tubes compliant with food-grade certifications?

Yes. DLSS provides tubing compliant with EN 10216-5, ASTM A270, and 3-A Sanitary Standards, with optional documentation for FDA and EHEDG review.

Q3: Can I use the same heat exchanger for multiple food products?

Yes, provided proper CIP protocols are followed and materials are non-reactive with all media.

Contact Us

DLSS supports food & beverage equipment manufacturers, system integrators, and end-users with certified stainless steel tubing and expert consultation for food-safe applications.

- Surface finish control

- 100% PMI and documentation

- Global shipping and packaging for sanitary applications

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Ensure food safety and heat exchanger efficiency—with DLSS.