With urban centers pushing for net-zero construction and energy-efficient design, HVAC systems—heating, ventilation, and air conditioning—have become the heart of green buildings.

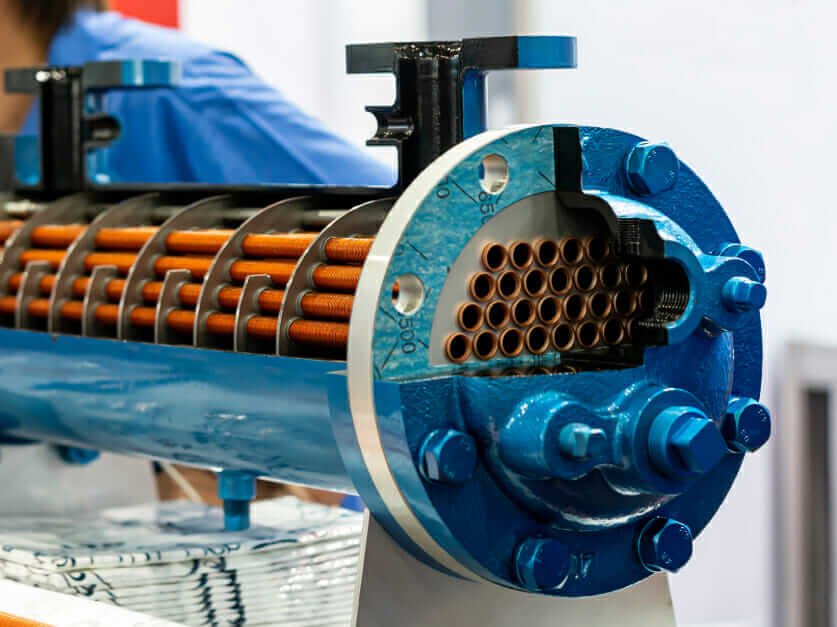

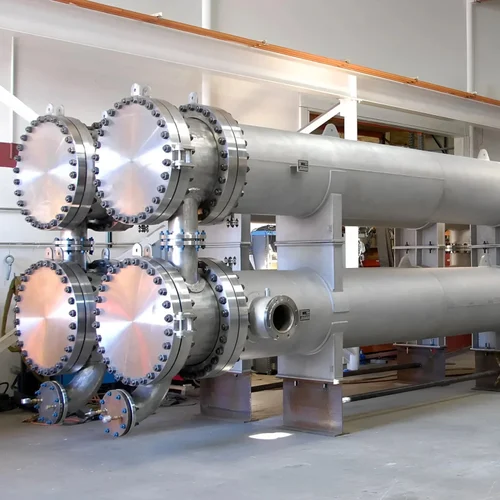

This shift is driving new demand for stainless steel heat exchanger tubes, used in chilled water systems, heat pumps, condenser units, and energy recovery modules.

1. Why Stainless Steel Is Replacing Copper and Galvanized Steel in HVAC

| Reason | Stainless Steel Advantage |

|---|---|

| Corrosion resistance | Especially in coastal cities and high-humidity zones |

| Longevity | 20+ year lifespan vs. galvanized or copper under acidic condensate |

| Sustainability | Recyclable, low carbon options available (ISO 14067) |

| Compatibility with modern refrigerants | Like R-32, CO₂, and ammonia |

| Aesthetics and hygiene | Preferred in hospitals, labs, and high-end public facilities |

Grades like TP304L, TP316L, and TP444 are now commonly used in HVAC coils, plate heat exchangers, and underfloor heating systems.

2. Where Tubes Are Used in Building HVAC Systems

| HVAC System Component | Tube Function |

|---|---|

| Chilled water coils | Transfer heat from indoor air to chilled water loop |

| Condenser coils | Discharge building heat to outdoor air or cooling tower |

| Heat pumps | Source/sink-side heat transfer for heating/cooling |

| Energy recovery systems (ERV) | Recover heat from exhaust air |

| Radiant floor heating | Circulate warm water through stainless tube circuits |

3. Global Trends in HVAC Tube Applications

| Region | Trend | Tube Impact |

|---|---|---|

| Europe | Strict energy codes (e.g., REACH, ErP) | High-efficiency TP316L coil tubing |

| Southeast Asia | Green building boom in Malaysia, Singapore | Salt-resistant TP304L U-bent tubes |

| USA & Canada | Electrification of heating (heat pumps) | Stainless steel replaces copper in aggressive condensate systems |

| China | Passive building design in Tier-1 cities | Stainless spiral coils in heat recovery ventilation |

According to the IEA, global heat pump sales grew by over 11% in 2023, especially in regions targeting building decarbonization.

4. Why Architects and MEP Designers Specify Stainless Tube

- Low maintenance lifecycle

- Fire safety and pressure resistance

- Certified materials with traceability (EN10204 3.1)

- Polished or bright-annealed surface finish for visible installations

- U-bent and coiled tubes for compact units

DLSS supplies HVAC-grade ASTM A249 / A269 / A213 tubes with tight tolerances, smooth ID surfaces, and custom lengths for chiller OEMs and contractors.

Frequently Asked Questions (FAQ)

Q1: What surface finish is typical for HVAC stainless steel tubes?

A: Polished or bright annealed finish with Ra ≤ 0.6 µm for thermal efficiency and hygiene.

Q2: Can stainless steel tubes handle modern refrigerants like CO₂ or ammonia?

A: Yes. TP316L and TP444 are commonly used with R-744 (CO₂), and are resistant to acidic byproducts in ammonia-based systems.

Q3: Are stainless steel HVAC tubes used only in commercial buildings?

A: Not anymore. High-end residential, hospitals, and even prefab housing are adopting stainless steel coils for lifespan and quality.

Q4: What packaging is preferred for HVAC coils and tubes?

A: Tubes are capped, plastic-wrapped, bundled in protective foam, and labeled with P.O., alloy, and length. U-bent coils are often crated or framed.

Conclusion: HVAC Tubes Are the Invisible Backbone of Green Buildings

Green building standards are rising. HVAC systems are getting smarter. But without the right tubing—durable, clean, and efficient—these systems can’t perform.

Stainless steel heat exchanger tubes offer the performance, lifespan, and environmental compliance required by next-generation HVAC applications.

At DLSS, we’re proud to support global HVAC and construction leaders with tailored stainless solutions for a greener, healthier future.