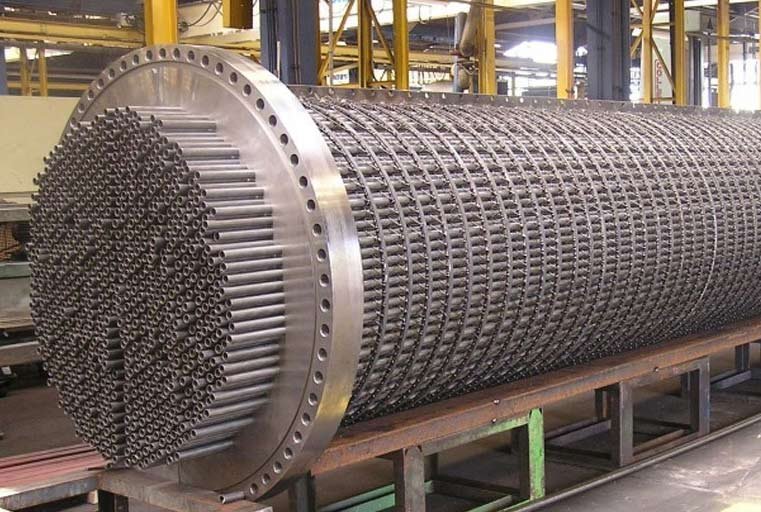

Whether in power plants, chemical facilities, HVAC systems, or food processing lines, heat exchanger efficiency directly impacts energy consumption, process reliability, and operating cost. Over time, even well-designed systems can suffer from performance degradation due to fouling, improper flow, or suboptimal configurations.

This article outlines practical and engineering-proven methods to improve the efficiency of shell-and-tube and plate heat exchangers, with recommendations on materials, flow management, surface treatment, and maintenance best practices.

Why Efficiency Declines Over Time

As noted in Wikipedia – Heat Exchanger, performance is governed by the overall heat transfer coefficient (U), which is influenced by:

- Fouling on heat transfer surfaces

- Flow regime (laminar vs turbulent)

- Material thermal conductivity

- Temperature differential and fluid properties

- Mechanical design and cleanliness

Efficiency drops can lead to 20–50% more energy usage, increased pressure loss, and reduced throughput.

Top 7 Strategies to Improve Heat Exchanger Efficiency

1. Increase Flow Turbulence

Transitioning from laminar to turbulent flow increases heat transfer by improving mixing at the boundary layer.

How:

- Use baffles or turbulators in shell-side flow

- Reduce tube diameters for same flow rate

- Maintain optimal Reynolds number (>2,300)

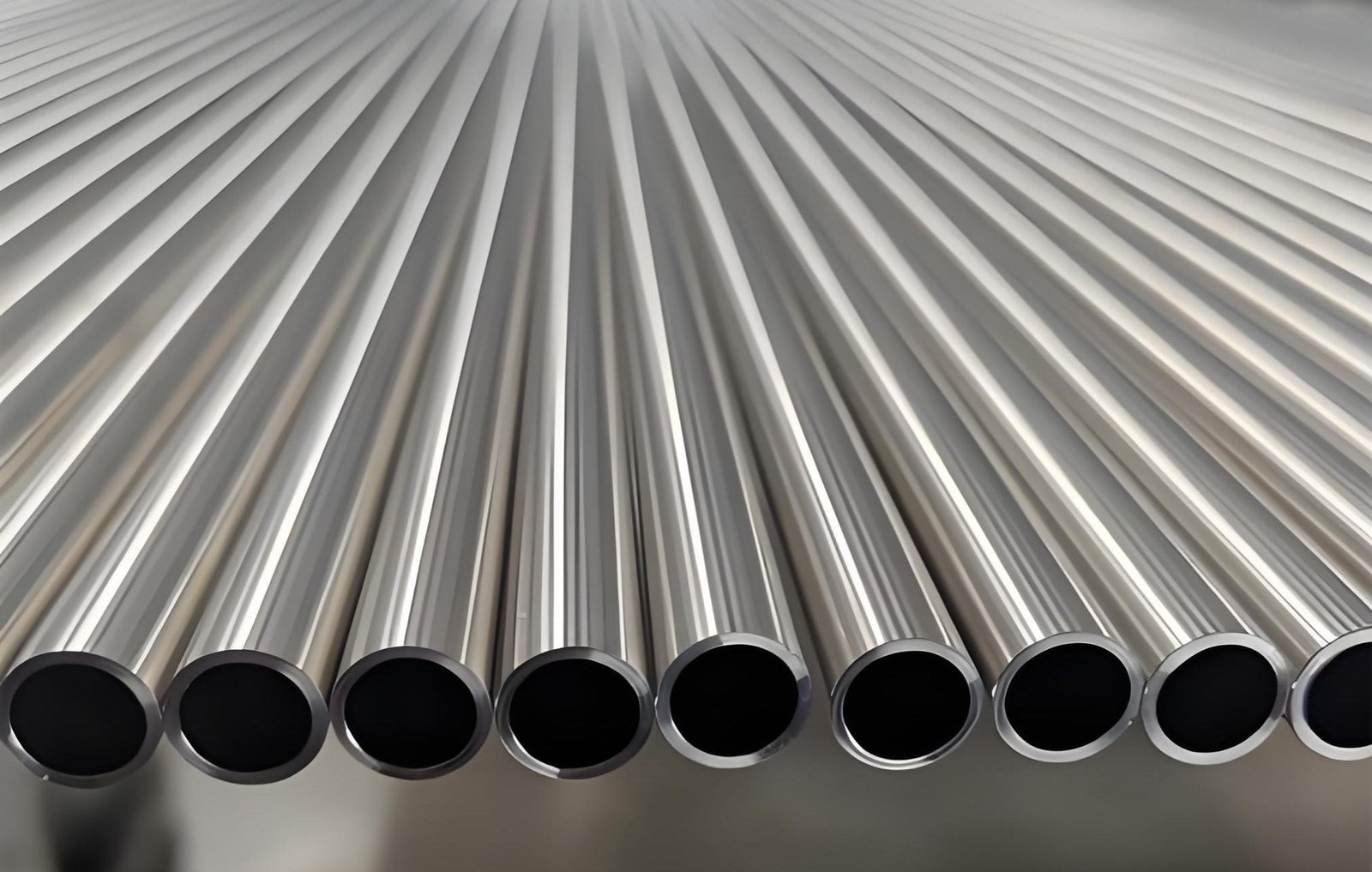

2. Upgrade Tube Material

Material matters. The thermal conductivity of the tube wall has a significant effect on exchanger performance.

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Copper | ~380 |

| Aluminum | ~205 |

| Stainless Steel 316L | ~16 |

| Titanium | ~21 |

| Incoloy/Hastelloy | ~11–15 |

While copper performs best thermally, stainless steel, duplex, and titanium provide superior corrosion resistance and longevity. Choose materials that balance thermal transfer and durability based on your fluid and operating conditions.

Explore materials: DLSS Stainless Tube Solutions

3. Apply Surface Enhancements

Improving surface conditions inside the tubes helps reduce fouling and enhances thermal exchange:

- Polished or bright-annealed finishes reduce roughness and biofilm attachment

- Ribbed or corrugated tubes increase internal turbulence

- Coatings (e.g., Teflon) resist corrosion or biological growth

4. Optimize Flow Arrangement

Choose the right configuration:

- Counterflow provides the best temperature gradient

- Crossflow is compact but less efficient

- Multi-pass increases contact time and turbulence

Ensure even fluid distribution to avoid dead zones and flow maldistribution.

5. Regular Cleaning and Maintenance

Refer to our Heat Exchanger Cleaning Guide for in-depth techniques.

- CIP (Clean-In-Place) for plate heat exchangers

- Mechanical brushing for shell-and-tube systems

- Hydroblasting for heavy deposits

- Clean every 6–12 months or based on performance data

6. Prevent Scaling and Fouling

Use pretreatment systems such as:

- Water softeners

- Filters and strainers

- Biocide dosing

- Anti-scaling agents

Monitor fouling factors and fluid chemistry to reduce downtime and cleaning frequency.

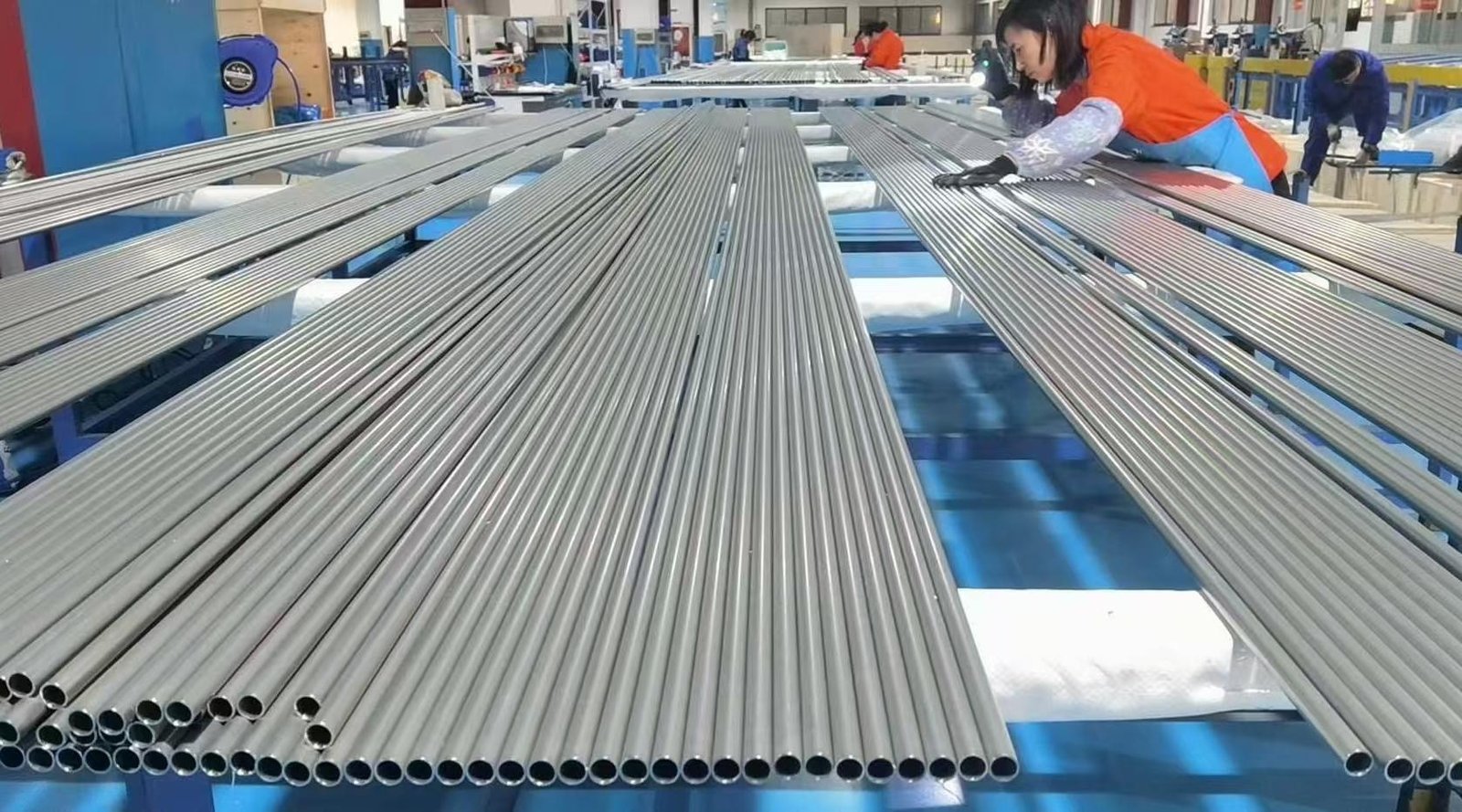

7. Use High-Quality Tubes from Trusted Manufacturers

Precision-manufactured seamless tubes ensure:

- Consistent wall thickness and flow area

- Leak-proof performance under high pressure

- Minimal roughness for lower friction losses

- Compliance with international standards (ASME, ASTM, PED)

DLSS provides:

- U-bent and straight tubes in stainless, Duplex, and titanium

- Surface finishes as low as Ra ≤ 0.4 µm

- Custom cut-to-length, hydro test, eddy current test

Frequently Asked Questions (FAQ)

Q1: How do I calculate if my exchanger is underperforming?

Compare actual outlet temperatures and pressure drops against design specs. A decline signals fouling or flow disruption.

Q2: Will changing the tube material alone improve efficiency?

Not always. It helps with longevity and corrosion but may require flow changes or enhanced surfaces for major impact.

Q3: Can I retrofit my exchanger with better tubes?

Yes. In many cases, tube bundles can be replaced or upgraded while retaining the shell or frame.

Q4: Does fouling affect plate and tubular exchangers equally?

No. Plate units foul faster with dirty fluids but are easier to clean. Shell-and-tube units are more tolerant but harder to access.

Contact Us

DLSS helps industrial clients optimize thermal performance through premium tubing solutions engineered for energy-efficient heat exchange.

- Expert material guidance

- High-finish seamless tube production

- Tubes for steam, corrosive fluids, food-grade, or geothermal systems

- Over 40 countries served

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Let DLSS support your next high-efficiency heat exchanger project.