Latin America (LATAM) is becoming an increasingly important region for stainless steel seamless tube suppliers—especially in the energy, mining, petrochemical, and food sectors. Countries like Brazil, Mexico, Argentina, and Chile are actively investing in infrastructure modernization, oil & gas projects, and renewable energy systems, all of which require heat exchangers, boilers, and industrial piping built with corrosion-resistant, high-performance materials.

In this blog, we’ll explore the key drivers of LATAM’s stainless steel tube demand, current project trends, and how DLSS Pipeline is supporting EPCs and distributors in the region.

1. Why Latin America Matters

A. Energy Modernization

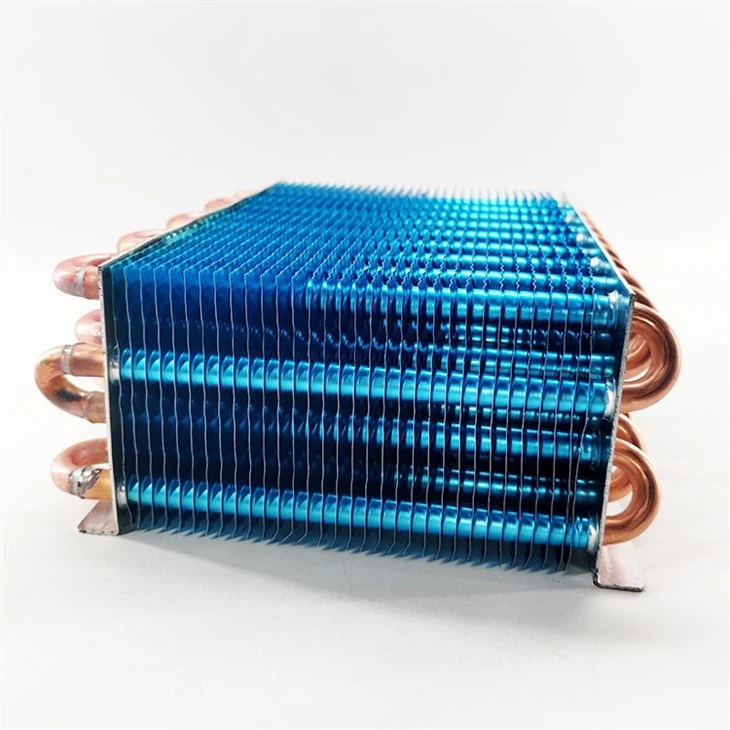

Many LATAM countries are upgrading aging thermal power and oil refining facilities. These brownfield projects rely heavily on U-bend heat exchanger tubes, duplex stainless, and high-alloy solutions.

B. Export-Oriented Mining & Petrochemical Expansion

Mining (Chile, Peru, Brazil) and chemical manufacturing (Argentina, Colombia) require cooling and process piping resistant to acidic or abrasive environments—where 904L, 317L, and 2205 duplex are preferred.

C. Strong Growth in Food & Beverage Processing

LATAM is a global food exporter. Dairy, brewing, and juice industries rely on hygienic seamless tubes with bright annealed (BA) finishes for CIP, pasteurization, and heat exchange.

D. Increasing Local Technical Standards

Many projects now require compliance with international norms such as ASME SA213, EN 10216-5, and PED 2014/68/EU—favoring global suppliers like DLSS who offer full material certification.

2. Key Markets in Focus

| Country | Industry Drivers | Tube Demand Characteristics |

|---|---|---|

| Brazil | Refining, biodiesel, food industry | U-tube, BA finish, 316L/2205 |

| Mexico | Oil & gas, power retrofit, chemical export | ASME-compliant, pickled seamless tubes |

| Argentina | Mining, fertilizer, brewery | Duplex grades, high corrosion resistance |

| Chile | Copper mining, desalination | 904L, 2507 super duplex, tight tolerances |

| Peru | Industrial water systems, pulp & paper | Long-length straight tubes, export packaging |

3. DLSS Value for Latin American Clients

- Export-ready packaging (crates, caps, seaworthy oil coating)

- Tube labeling in Spanish/English per contract

- TPI/SGS/Lloyd’s inspections available

- Spanish-speaking support on request

- Short lead times for U-tubes and BA finish

DLSS supports stainless tube exports for Latin American energy and industrial projects from our production base in China. Learn more: www.dlsspipeline.com

Frequently Asked Questions (FAQ)

Q1: Are seamless tubes used more than welded in LATAM?

Yes—for high-pressure, high-purity, or corrosive systems (like boilers, exchangers), seamless tubes are the norm.

Q2: What are the most common grades ordered from LATAM?

TP316L, TP317L, 2205 duplex, and increasingly, 904L and S32750 for mining and desalination.

Q3: Can DLSS provide custom length and surface finish?

Absolutely. We offer custom cut-to-length, U-bending, BA, AP, and electropolishing options.

Conclusion

Latin America presents a promising opportunity for stainless steel tube exporters, with strong demand in energy transition, mining, and food-grade process industries. Local standards are aligning with global norms—creating a strong fit for reliable, certified, export-ready seamless tube manufacturers.

DLSS Pipeline is ready to serve Latin American clients with tailored solutions, competitive pricing, and full technical support.