1. Introduction

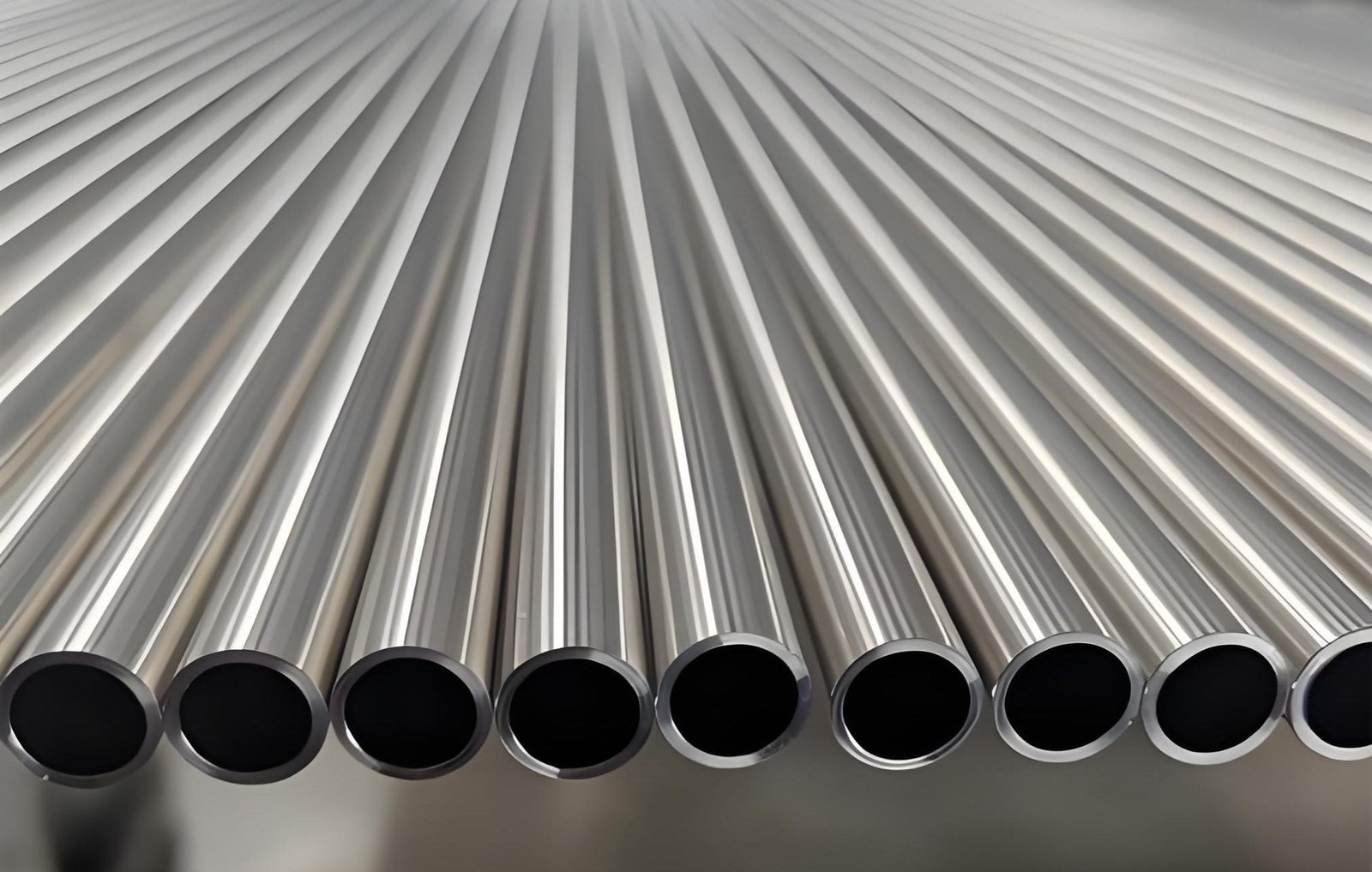

Liquefied Natural Gas (LNG) terminals and oil refineries operate under some of the most challenging conditions in the energy sector. Piping systems in these facilities are constantly exposed to high pressure, fluctuating temperatures, and corrosive media such as hydrogen sulfide, chlorides, and acids. Nickel alloy pipes, including Inconel 625 (ASTM B444) and Incoloy 825 (ASTM B423), have become the preferred choice to ensure safety, reliability, and long service life in LNG and refinery projects.

2. Why Nickel Alloy Pipes Are Essential

- High Corrosion Resistance: Withstand sour gas, chloride-rich environments, and acidic conditions where stainless steel fails.

- Strength at High Temperatures: Maintain mechanical properties at cryogenic (-196°C) and elevated temperatures (>600°C).

- Resistance to Sulfide Stress Cracking: Meet NACE MR0175/ISO 15156 requirements for sour service.

- Longevity: Reduce maintenance costs and unplanned shutdowns in refinery and LNG operations.

Reference: Nickel Alloys – Wikipedia.

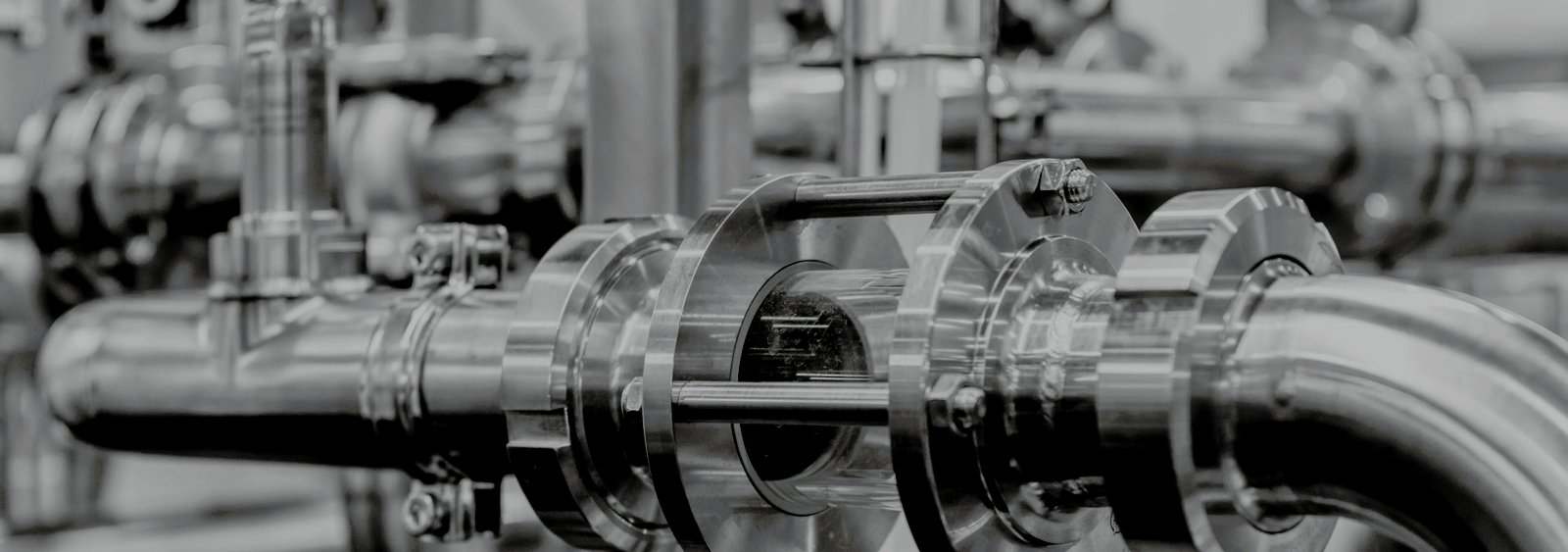

3. Applications in LNG Industry

- Cryogenic Piping: Nickel alloys maintain toughness at LNG storage (-162°C).

- Heat Exchangers: Alloy 625 tubes used in LNG regasification units.

- Seawater Cooling Systems: Inconel 625 pipes resist seawater corrosion in offshore LNG facilities.

- Offloading Terminals: High-strength nickel alloys ensure reliability in harsh marine environments.

4. Applications in Refineries

- Hydroprocessing Units: Alloy C-276 and 625 pipes handle aggressive acids in hydrocrackers.

- Sulfuric Acid Alkylation Units: Incoloy 825 pipes offer excellent resistance to sulfuric and phosphoric acids.

- Desulfurization Plants (FGD): Nickel alloys withstand high chloride and oxidizing conditions.

- Flare Systems and High-Temperature Piping: Inconel pipes provide strength and oxidation resistance.

5. Key ASTM Standards for Nickel Alloy Pipes

- ASTM B444 – Seamless Inconel 625 pipe.

- ASTM B423 – Seamless Incoloy 825 pipe.

- ASTM B622 / B619 / B626 – Hastelloy C-276 seamless and welded pipes.

- Certification Requirements: EN 10204 3.2, PED, NACE MR0175/ISO 15156 compliance.

6. DLSS Supply Strengths

At DLSS, we supply nickel alloy pipes and tubes specifically for LNG and refinery applications:

- Grades: Inconel 625, Incoloy 825, Hastelloy C-276.

- Standards: ASTM B444, B423, B622.

- Third-party inspection: TÜV, DNV, LR, ABS.

- Project documentation: EN 10204 3.1/3.2 MTC, NACE compliance reports.

- Flexible production for seamless and welded pipes, plus U-bend tubes for heat exchangers.

7. Conclusion & Call to Action

Nickel alloy pipes are indispensable in LNG and refinery projects, where corrosion, sour gas, and extreme temperatures pose significant challenges. By choosing Inconel 625, Incoloy 825, or Hastelloy C-276, project stakeholders secure reliability and long-term cost savings.

For EPC contractors and refinery operators seeking ASTM-compliant nickel alloy pipes, DLSS offers proven expertise and reliable delivery.

Contact us for quotations and technical datasheets.

info@dlsspipe.com | www.dlsspipeline.com