The shipbuilding industry continues to grow, with China, South Korea, and Japan accounting for nearly 90% of global ship output in 2023. As vessels are exposed to seawater corrosion, high pressure, and strict IMO environmental standards, the demand for corrosion-resistant stainless steel tubes and copper-nickel alloy pipes has never been higher.

At DLSS, we specialize in stainless steel tubes for shipbuilding, seamless marine pipes, and copper-nickel tubes for seawater systems, designed to meet the needs of global shipyards.

Material Comparison for Shipbuilding Pipes

To highlight why stainless steel and copper-nickel alloys are widely used in shipyards, here is a technical comparison of three major materials:

| Property | Carbon Steel | Stainless Steel (304/316) | Copper-Nickel Alloy (90/10, 70/30) |

|---|---|---|---|

| Corrosion Resistance (Seawater) | Poor – requires coatings, frequent maintenance | Good – resistant to chloride stress corrosion, suitable for seawater applications | Excellent – outstanding resistance to biofouling and seawater corrosion |

| Service Life in Marine Environment | 5–8 years (high maintenance) | 15–20 years | 20–25 years |

| Operating Temperature | Up to ~400°C | Up to ~600°C | Up to ~400°C |

| Strength at High Pressure | Medium | High – ideal for boilers, condensers, and pressure systems | Medium |

| Maintenance Requirements | Frequent painting, replacement, higher lifecycle cost | Moderate – stable long-term performance | Low – minimal maintenance needed |

| Cost (Initial vs Lifecycle) | Low initial cost, high long-term cost | Medium initial cost, balanced lifecycle cost | Higher initial cost, lowest lifecycle cost |

| Certifications | Limited marine approval | Certified by ABS, DNV, LR, BV | Widely approved by classification societies for seawater systems |

Key Applications in Shipyards

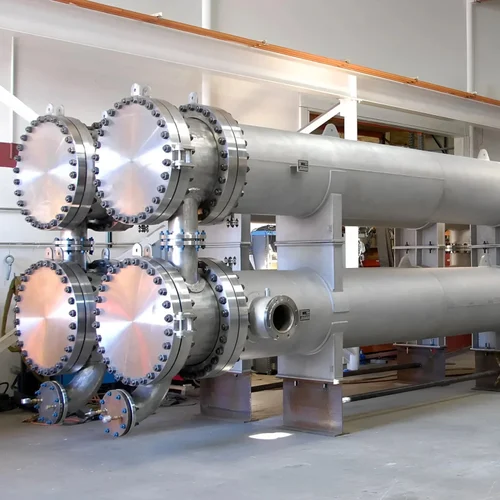

1. Heat Exchanger & Condenser Tubes

Heat exchangers represent 20–30% of total piping materials in vessel engine rooms. DLSS provides finned tubes and condenser tubes that ensure efficient thermal transfer under harsh seawater conditions.

2. Marine Boilers & Pressure Systems

Marine boilers operate at 6–8 MPa and over 500°C. DLSS supplies high-pressure stainless steel boiler tubes, manufactured to ASME BPVC standards and approved by all major classification societies.

3. Seawater Desalination Units

Cupronickel alloys (90/10, 70/30) extend service life up to 25 years, ensuring reliability in onboard desalination plants.

4. Auxiliary Systems (HVAC, Firefighting, Fuel & Lubrication)

Large vessels typically use 10–15 km of piping, where DLSS supplies marine piping solutions with superior corrosion resistance and long-term durability.

Why Shipyards Choose DLSS

- 30+ Years of Manufacturing Experience with shipyards and offshore projects.

- Certified by ABS, DNV, BV, LR, PED (EU Pressure Equipment Directive).

- Customization: Tubes up to 17.5 m in length, with tolerances of ±0.5% OD and ±7.5% WT.

- Comprehensive Testing: HT, ET, UT, RT, PMI, and third-party inspections (TPI).

- Global Reach: Exports to 56+ countries, packaging suitable for sea transport.

Customer Success Story

In 2024, DLSS delivered 12 km of copper-nickel finned tubes to a European LNG shipyard. Despite a tight 45-day lead time, all tubes passed BV inspection and third-party testing. The installed system has achieved 15% higher efficiency compared to traditional carbon steel tubes, extending the vessel’s operating cycle.

Conclusion

The shipbuilding sector is projected to exceed 55 million gross tons by 2026, driving demand for advanced materials. Stainless steel tubes and copper-nickel alloys offer shipyards longer service life, lower maintenance costs, and compliance with IMO environmental regulations.

Looking for corrosion-resistant stainless steel tubes for shipbuilding? Contact DLSS today and explore our marine piping solutions.