As industrial demands for thermal efficiency, space optimization, and corrosion resistance continue to grow, the design and selection of heat exchangers have become increasingly specialized. Beyond basic double tube systems, engineers often turn to more advanced pipe configurations to meet rigorous process requirements.

In this article, we explore three widely used and performance-driven heat exchanger types: the U-Tube Heat Exchanger, Shell and Tube Heat Exchanger, and Coiled Tube Heat Exchanger.

1. U-Tube Heat Exchanger: Space-Saving and Flexible

The U-tube heat exchanger features a bundle of U-shaped tubes housed within a shell. One fluid flows through the U-tubes, while another circulates around them inside the shell.

Advantages:

- Compact footprint

- Accommodates thermal expansion due to tube flexibility

- Cost-effective for high-pressure applications

Common Applications:

- Steam-to-liquid or liquid-to-liquid heat transfer

- Power generation

- Refineries and chemical plants

DLSS provides thin-walled U-bend stainless steel tubes with tight radius control, ideal for precision U-tube bundle manufacturing.

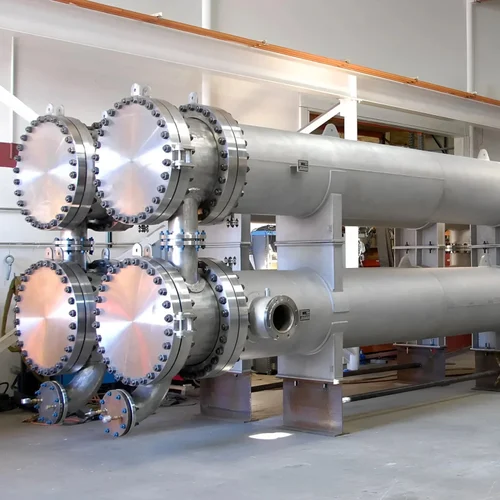

2. Shell and Tube Heat Exchanger: Industrial Standard

The shell and tube heat exchanger is the most widely used design in industries requiring high heat transfer capacity. It consists of multiple straight tubes enclosed in a cylindrical shell. Baffles may be added to direct fluid flow and increase turbulence for better thermal performance.

Key Benefits:

- Handles high pressure and high-temperature environments

- Easily scalable for large systems

- Facilitates multiple flow configurations (crossflow, counterflow, multipass)

Applications:

- Oil refining and petrochemical processes

- Boiler feedwater preheating

- Cooling tower loops

DLSS offers stainless steel and duplex alloy tubes that meet ASME, ASTM, and EN standards, making them suitable for shell-and-tube heat exchanger manufacturing worldwide.

3. Coiled Tube Heat Exchanger: High Efficiency in Compact Designs

Coiled tube heat exchangers use helically coiled or spiral tubes, often enclosed in a tank or shell. Their compact shape allows for a large surface area in a small volume, making them ideal for space-constrained systems.

Features:

- Enhanced heat transfer due to secondary flow patterns (Dean vortices)

- Low fouling design

- High mechanical strength under vibration

Use Cases:

- Solar thermal systems

- Chemical reactors

- Small-scale heat recovery units

Our seamless coiled stainless steel tubing ensures minimal leakage risk and excellent corrosion resistance, even under cyclic temperature conditions.

Why DLSS Tubing Fits These Designs

At DLSS, we specialize in precision stainless steel seamless tubes, offering key advantages for advanced heat exchanger applications:

- Tight tolerances and smooth inner surfaces for optimal flow

- Custom lengths, U-bends, and coiled configurations available

- Materials include TP304, TP316L, 2205, 2507, and nickel alloys

- Compliance with ASTM A213 / A269 / EN 10216-5 / JIS G3463 standards

Explore our manufacturing capabilities at www.dlsspipeline.com

Inquiries: info@dlsspipe.com