In the race to produce high-precision, high-reliability stainless steel seamless tubes for critical applications like heat exchangers, power plants, and offshore platforms, automation and quality control technologies are becoming true differentiators.

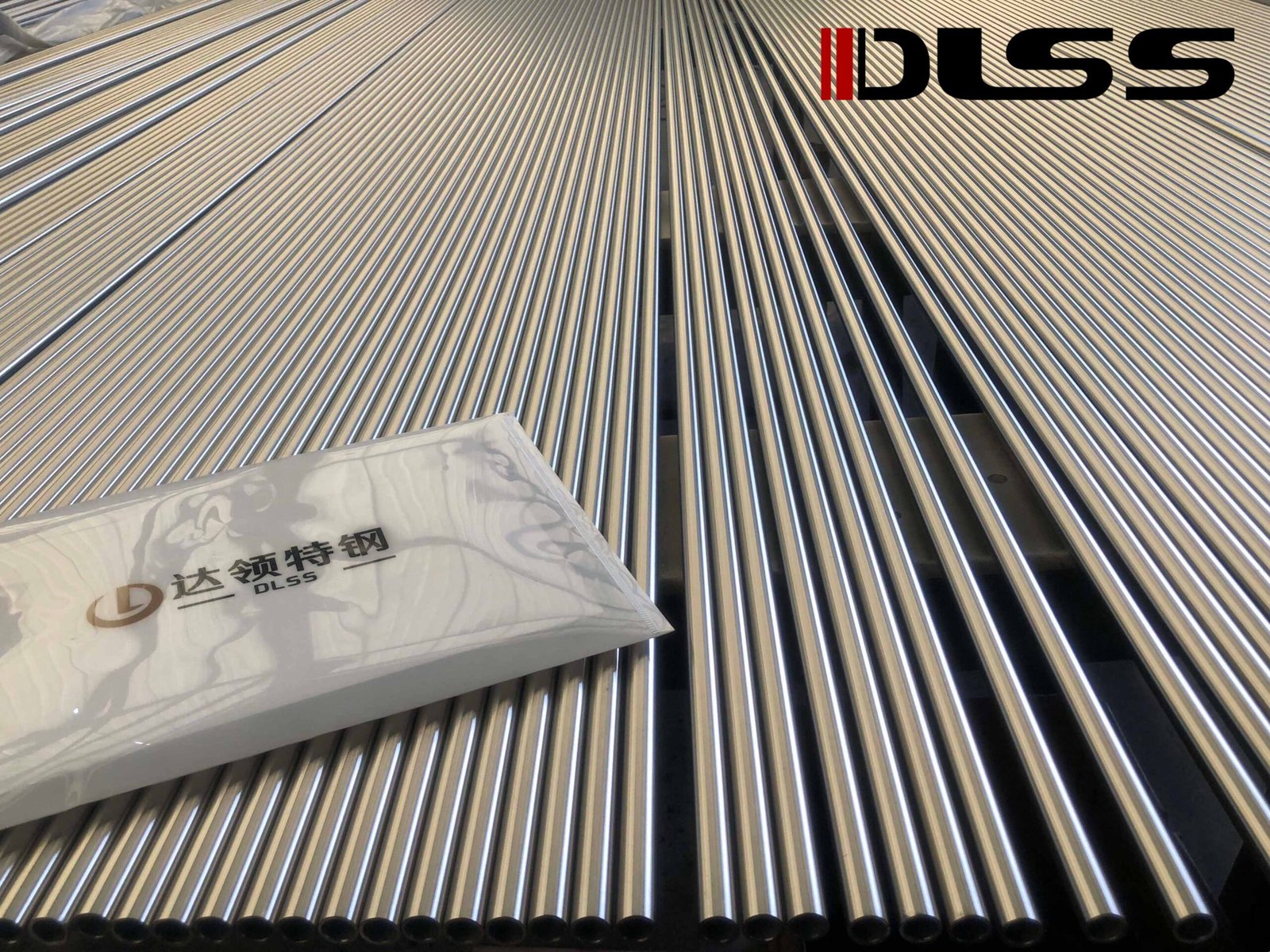

Modern tube manufacturers are no longer just metal processors—they are tech-enabled precision producers. At DLSS Pipeline, we’ve embraced this transformation to deliver consistent, export-ready stainless steel tubes that meet ASME, EN, and PED standards for global projects.

This article explores how automation, inline inspection, and data-driven quality control are revolutionizing stainless steel seamless tube production.

1. Why Manufacturing Needs More Than Just Steel

Customers today demand tubes that are:

- Dimensionally precise

- Surface-finished to specification (e.g., BA or AP)

- Free from micro-cracks, thinning, or inclusions

- Certified for international projects with full traceability

These quality standards cannot be consistently met without modernized equipment and inspection systems.

2. Key Automation Technologies in Tube Production

A. Cold Drawing Automation

- Servo-controlled drawing benches ensure uniform elongation

- Sensors monitor drawing force and deformation limits

- Enables consistent mechanical properties throughout the batch

B. Bright Annealing Furnaces with Atmosphere Control

- Uses hydrogen or nitrogen to avoid oxidation

- Fully enclosed to deliver clean, shiny, mirror-like finishes

- Programmable temperature and speed profiles minimize grain growth

C. Online Laser Measurement

- Real-time OD and WT monitoring

- +/-0.05 mm tolerance control or better

- Alerts operators of deviations instantly

D. Automatic Cutting and Chamfering

- Precision-cut tube ends, smooth edges, and burr-free finishes

- Improves weldability and fit-up for heat exchanger assembly

3. NDT and Final Inspection Technologies

Eddy Current Testing (ECT)

- 100% inline detection of surface cracks, voids, laminations

- Essential for boiler, condenser, and offshore tube applications

Ultrasonic Testing (UT)

- Evaluates wall thickness and detects internal defects

- Required for thicker duplex and super duplex tubes

Visual + Endoscopic Inspection

- Internal borescope checks for BA or polished tubes

- Verifies weld integrity (if applicable) and surface cleanliness

Surface Roughness Test (Ra)

- Ensures hygienic tubes meet Ra < 0.5 µm (for food/pharma)

- DLSS offers polishing or electropolishing per request

4. Digital Traceability and Smart QC

- Barcode and heat number tracking throughout production

- EN 10204 3.1 / 3.2 certificates generated with matching test data

- Support for third-party inspection (SGS, BV, TÜV, customer reps)

DLSS integrates digital batch logs, heat treatment records, and inspection snapshots into your documentation pack.

Frequently Asked Questions (FAQ)

Q1: Is all this automation really necessary for stainless steel tubes?

Yes—especially for export-grade tubing where tolerance, weldability, and appearance are critical.

Q2: Does DLSS offer test videos or digital inspection files?

Yes, we provide digital photos, NDT scan summaries, and even packing videos for customer review.

Q3: Can I request automatic sorting or bundling by length/diameter?

Absolutely. Our cutting and packaging lines support smart sorting for job-site-ready delivery.

Conclusion

In today’s global market, precision = trust. Stainless steel seamless tubes must not only meet dimensional standards, but also prove their performance through real-time inspection and verifiable quality control.

At DLSS Pipeline, we invest in automated production, certified NDT, and export documentation systems—so your project starts with tubes that are right the first time.