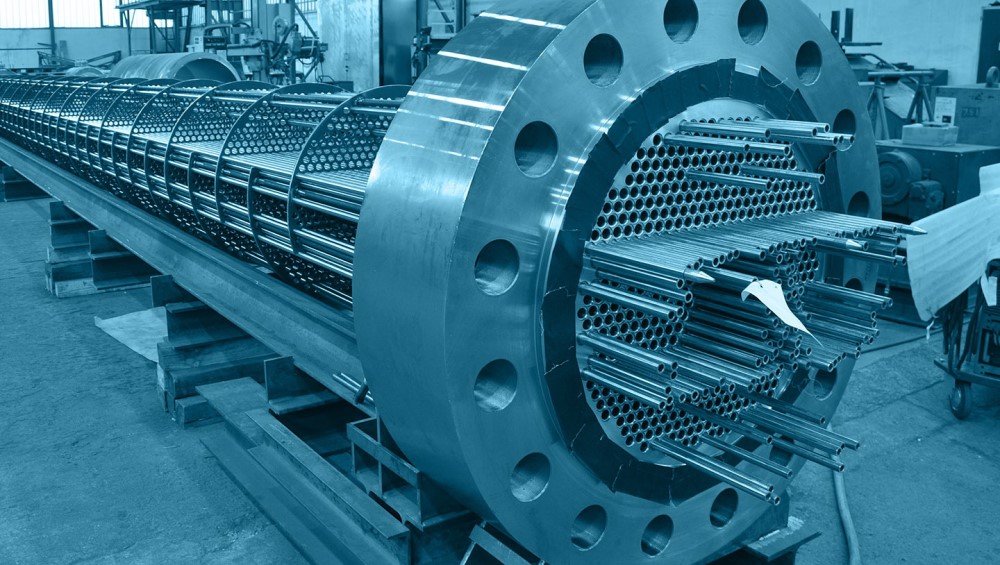

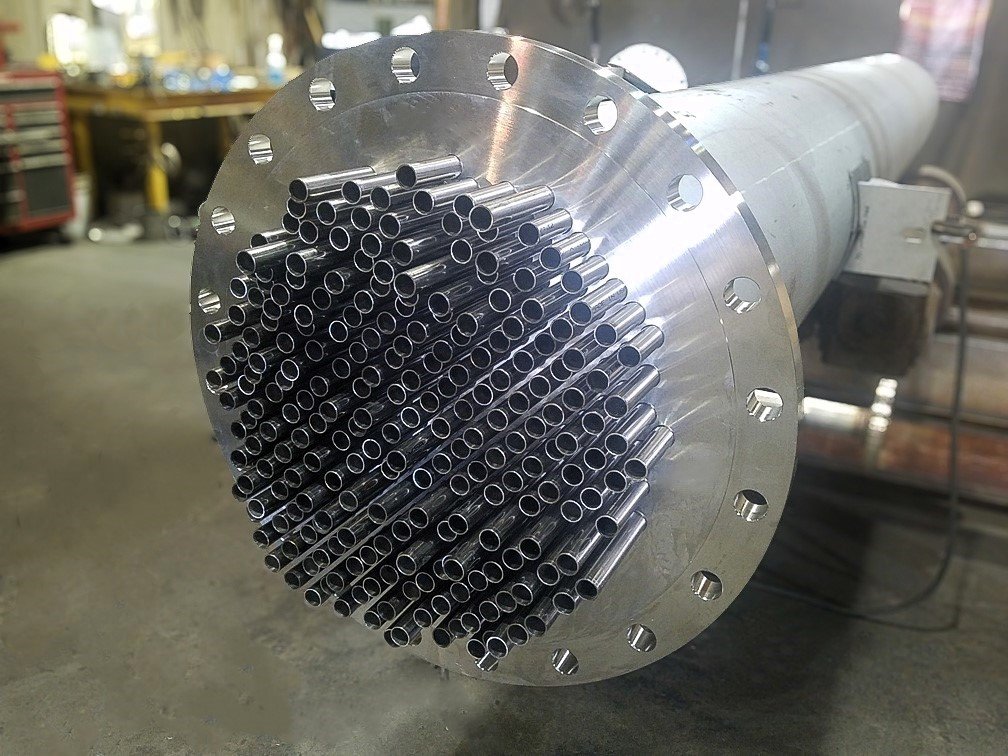

In environments where moisture, saltwater, or harsh chemicals are present, corrosion resistance is one of the most critical factors in heat exchanger performance. Extruded finned tubes are specially designed to meet these challenges, making them the go-to choice for marine and offshore industries.

If you want to understand the full range of finned tube options, read Different Types of Finned Tubes and Their Applications. For more on industrial durability, check High-Frequency Welded Finned Tubes: Advantages and Ideal Applications.

Manufacturing Process

In an extruded finned tube, a sleeve of aluminum or copper is placed over the base tube, and the finned profile is formed by extruding the sleeve onto the tube under high pressure. This results in:

- A tight mechanical bond between fin and tube

- Complete coverage of the base tube for corrosion protection

- Enhanced surface area for efficient heat transfer

Key Advantages

- Exceptional Corrosion Resistance – Full coverage of non-ferrous fin material shields the base tube from aggressive environments.

- Superior Heat Transfer – Conductive metals like aluminum and copper optimize thermal performance.

- Long Service Life – Minimal maintenance even in humid or saline environments.

- Aesthetic Finish – Smooth, uniform fins with no weld spatter or oxidation marks.

Ideal Applications

- Seawater-Cooled Condensers – In desalination plants and coastal power stations.

- Offshore Oil & Gas Platforms – For gas coolers, condensers, and heat recovery systems.

- Marine HVAC Systems – Corrosion-resistant cooling coils in ships and submarines.

- Chemical Processing Plants – In corrosive gas or vapor cooling applications.

Maintenance Tips

Even corrosion-resistant tubes benefit from regular inspections:

- Check for biofouling or marine growth

- Monitor fin integrity and bonding

- Implement cleaning as part of a Heat Exchanger Maintenance Checklist

Conclusion

Extruded finned tubes combine durability, high thermal efficiency, and superior corrosion resistance, making them ideal for marine and offshore environments where equipment reliability is paramount.

DLSS produces customized extruded finned tubes with a range of materials and specifications to match your project requirements.

Contact our experts via www.dlsspipeline.com or email info@dlsspipe.com for technical advice and a personalized quote.