1. Introduction – Heat Exchanger Tube Materials

Selecting the right heat exchanger tube material is critical for optimizing performance, extending service life, and minimizing maintenance costs.

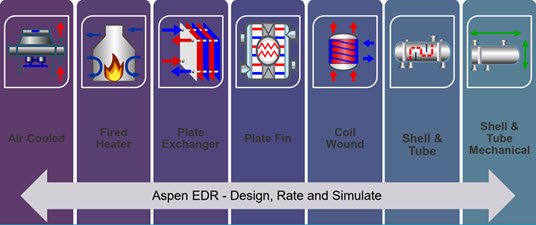

This article compares stainless steel, copper, and titanium—three of the most common materials used in shell and tube as well as plate heat exchanger designs.

For related topics, see Best Material for Seawater Heat Exchanger, Heat Exchanger Maintenance Checklist, and Shell and Tube Heat Exchanger Design Considerations.

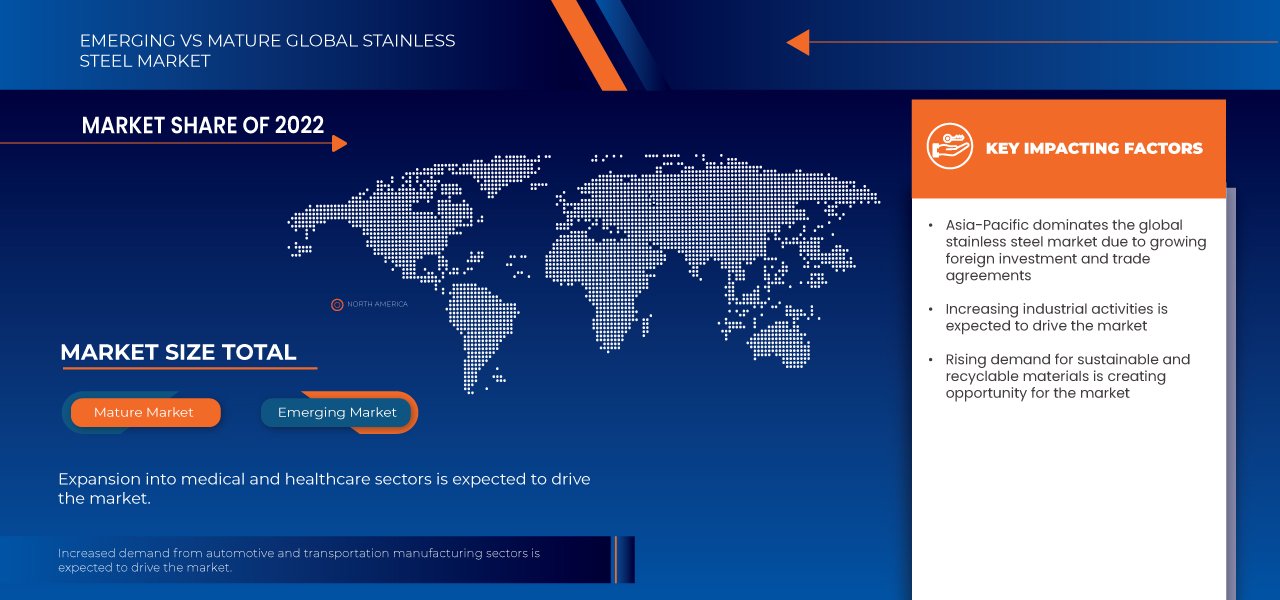

2. Stainless Steel Tubes

Advantages:

- Excellent corrosion resistance in many industrial environments

- High strength at elevated temperatures

- Cost-effective compared to titanium

- Available in multiple grades such as 304L, 316L, and duplex stainless steels

Disadvantages:

- Lower thermal conductivity than copper

- Susceptible to chloride stress corrosion cracking in high-salt conditions unless duplex or super duplex grades are used

Applications:

- Food processing, chemical plants, HVAC, and general industrial heating/cooling

3. Copper Tubes

Advantages:

- High thermal conductivity for efficient heat transfer

- Natural antimicrobial properties (ideal for potable water systems)

- Easy to fabricate and join

Disadvantages:

- Poor resistance to strong acids and ammonia

- Can corrode quickly in seawater without protective measures

- Shorter service life in aggressive industrial conditions

Applications:

- Domestic hot water, refrigeration, low-pressure HVAC systems

4. Titanium Tubes

Advantages:

- Exceptional corrosion resistance in seawater and aggressive chemicals

- High strength-to-weight ratio

- Longest expected service life among common materials

- For marine service specifics, see best materials for seawater heat exchangers, and for system-level choices compare plate vs shell and tube designs.

Disadvantages:

- High initial cost

- More difficult to fabricate than stainless steel or copper

Applications:

- Marine condensers, offshore oil & gas, desalination plants

5. Comparison Table

| Property | Stainless Steel | Copper | Titanium |

|---|---|---|---|

| Corrosion Resistance | High (varies by grade) | Moderate | Excellent |

| Thermal Conductivity | Moderate | High | Moderate |

| Strength | High | Low-Medium | High |

| Cost | Medium | Low-Medium | High |

| Lifespan | Long | Short-Medium | Very Long |

| Seawater Suitability | Good (Duplex/Super Duplex) | Poor | Excellent |

6. Real-World Example

A marine engineering company replaced copper condenser tubes with titanium for seawater service. The upgrade eliminated frequent corrosion-related failures and extended the maintenance interval from 1 year to over 10 years, despite the higher upfront investment.

7. Conclusion

Choosing the right tube material depends on operating environment, budget, and desired lifespan.

- Stainless steel offers a balance between cost and corrosion resistance.

- Copper provides high heat transfer but requires careful corrosion management.

- Titanium delivers unmatched durability in seawater and aggressive fluids.

For more on preventing corrosion and fouling, read 7 Effective Ways to Prevent Fouling in Heat Exchangers and 5 Proven Ways to Improve Heat Exchanger Efficiency.

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading