1. Introduction – Plate vs Shell and Tube Heat Exchanger

When selecting a heat exchanger for your application, one of the most common decisions is between a plate heat exchanger (PHE) and a shell and tube heat exchanger (STHE). Both designs have unique advantages and limitations.

This guide compares the two to help you choose the right solution based on efficiency, maintenance, cost, and application suitability.

For related insights, see Shell and Tube Heat Exchanger Design Considerations, 5 Proven Ways to Improve Heat Exchanger Efficiency, and Heat Exchanger Maintenance Checklist.

2. Design Differences

Plate Heat Exchanger (PHE)

- Consists of multiple thin plates with corrugated surfaces to increase turbulence and heat transfer area.

- Compact design, ideal for space-constrained installations.

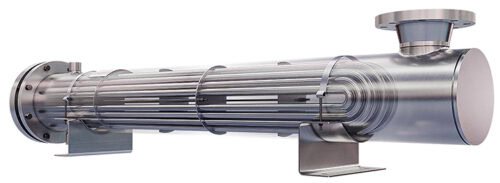

Shell and Tube Heat Exchanger (STHE)

- Comprises a cylindrical shell containing a bundle of tubes.

- Handles higher pressures and temperatures, suitable for heavy-duty industrial applications.

3. Efficiency Comparison

- PHE: Higher heat transfer efficiency due to increased surface area and turbulence.

- STHE: Lower efficiency per unit volume but better for handling large temperature differences and phase changes.

See 5 Proven Ways to Improve Heat Exchanger Efficiency for optimization tips.

4. Maintenance and Cleaning

- PHE: Easier to clean by disassembling plates; however, gasket replacement can be frequent in high-temperature or chemical service.

- STHE: Cleaning can require tube bundle removal, but design allows for robust materials like duplex stainless steel for extended life. See Heat Exchanger Maintenance Checklist for best practices.

- For heavy-duty STHE projects, review shell and tube design considerations, and pick suitable tube alloys via tube materials comparison.

5. Cost Considerations

- PHE: Lower initial cost for small to medium duty applications.

- STHE: Higher initial cost but potentially lower lifecycle cost in aggressive or high-pressure services due to longer durability.

6. Application Suitability

- PHE: Food & beverage, HVAC, low-viscosity fluids.

- STHE: Oil & gas, chemical processing, marine cooling, steam condensing.

7. Real-World Example

A chemical plant replaced a plate heat exchanger with a duplex stainless steel shell and tube design to handle seawater cooling. The change reduced maintenance frequency by 50% and improved system uptime, offsetting the higher initial cost within two years.

8. Conclusion

Choosing between a plate heat exchanger and a shell and tube heat exchanger depends on your process requirements, space constraints, budget, and maintenance capabilities.

For marine and aggressive environments, material selection is critical—see Best Material for Seawater Heat Exchanger for guidance. For fouling prevention, read 7 Effective Ways to Prevent Fouling in Heat Exchangers.

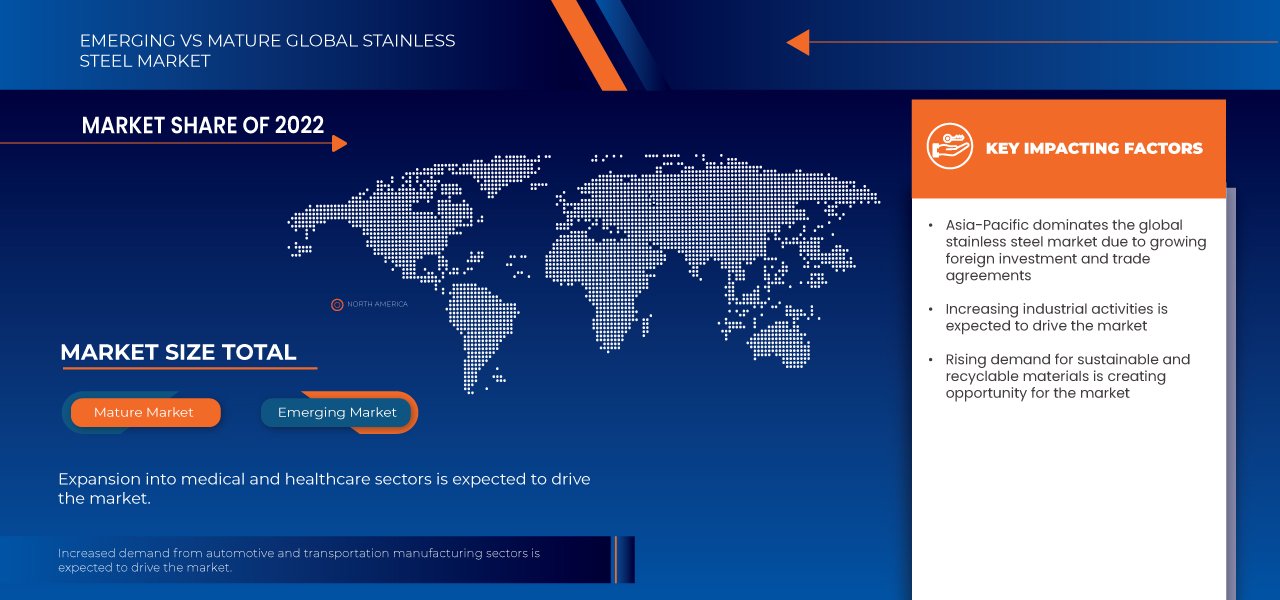

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading

- Shell and Tube Heat Exchanger Design

- Heat Exchanger Tube Materials

- Sizing a Shell and Tube Heat Exchanger