Introduction

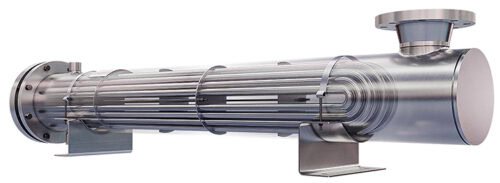

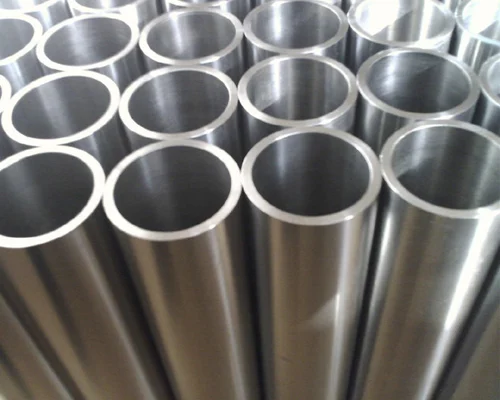

Heat exchangers operating in corrosive and high-pressure environments require tube materials with superior mechanical properties and corrosion resistance. One typical customer requirement highlights the importance of super duplex seamless tubes (SA789 S32205) in long-length applications. With outside diameters of 25.4 mm, thin wall thickness, and lengths exceeding 18 meters, these tubes represent a challenging yet essential solution for modern heat exchanger design.

Customer Requirement Example

A customer recently outlined the following specification for seamless duplex tubes:

- Material: ASME SA789 S32205 Duplex (Super Duplex grade)

- Outside Diameter (OD): 25.4 mm

- Minimum Wall Thickness: 0.9 mm

- Tube Length: 18,290 mm

- Quantity: 4,600 pieces

This configuration demonstrates a focus on extended tube lengths with thin walls, aiming to improve efficiency while minimizing welding joints inside tube bundles.

Why Super Duplex S32205?

Super Duplex stainless steel S32205 is a preferred choice for high-performance heat exchanger tubes due to its unique balance of strength and corrosion resistance.

- High Corrosion Resistance: PREN (Pitting Resistance Equivalent Number) above 35 ensures protection against pitting and crevice corrosion.

- Strength Advantage: Nearly twice the yield strength of standard austenitic stainless steels, allowing thinner walls without compromising safety.

- Stress Corrosion Cracking Resistance: Particularly effective in chloride-rich environments such as seawater cooling or geothermal brine applications.

- Extended Lifespan: Long-term reliability reduces maintenance costs and downtime.

Technical Challenges in Long-Length Seamless Tubes

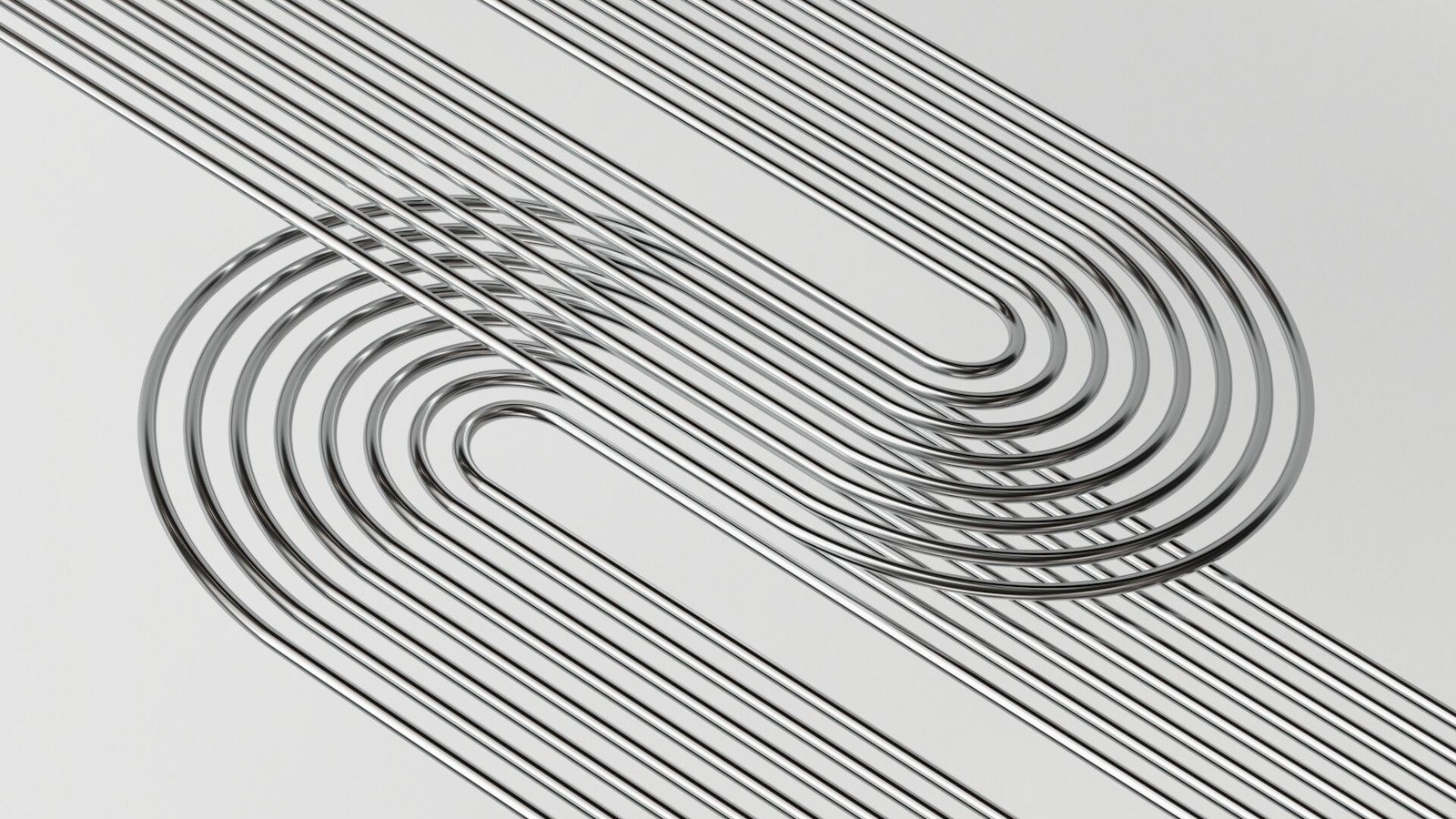

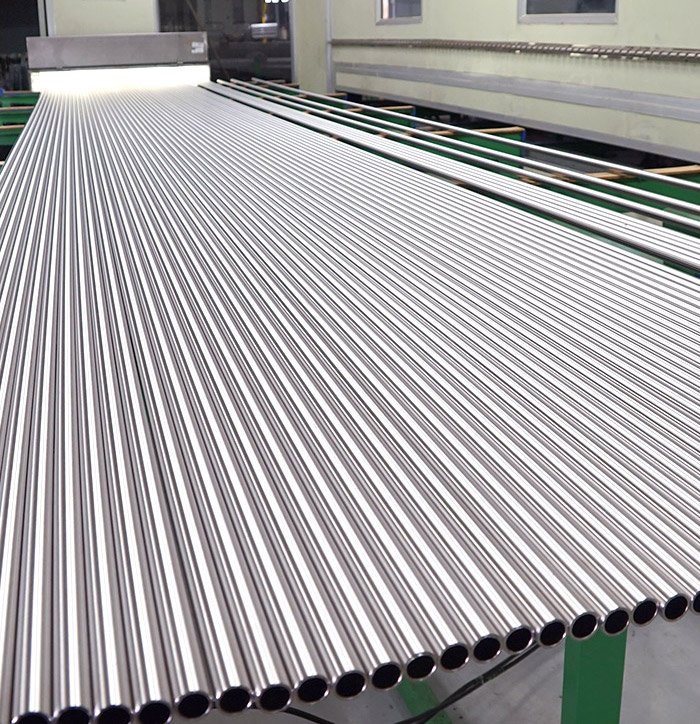

Producing tubes with 0.9 mm wall thickness and over 18 meters length is technically demanding:

- Straightness Control: Ensuring the tube maintains straight alignment over long lengths to fit into precise heat exchanger tube sheets.

- Thin-Wall Strength: Preventing collapse or ovality during cold drawing and heat treatment.

- Surface Quality: Maintaining smooth inner and outer surfaces for optimal heat transfer and reduced fouling.

- Packaging & Handling: Protecting long tubes during shipping requires reinforced wooden crates, internal capping, and often nitrogen purging.

DLSS Manufacturing Solutions

DLSS provides engineering-grade solutions to address these challenges:

- Cold Drawing Precision: Advanced processes maintain tight tolerances for OD, wall thickness, and straightness.

- Bright Annealing & Solution Heat Treatment: Restores corrosion resistance and refines microstructure.

- Full QA Documentation:

- EN 10204 3.1 certificates (optionally 3.2 with third-party inspection)

- 100% Eddy Current & Hydrostatic Testing

- PMI (Positive Material Identification) for every batch

- Complete ITP (Inspection and Test Plan) dossier

- Surface & Packaging: Acid pickling/passivation, optional bright finish, capped ends, nitrogen purging, and seaworthy export packaging.

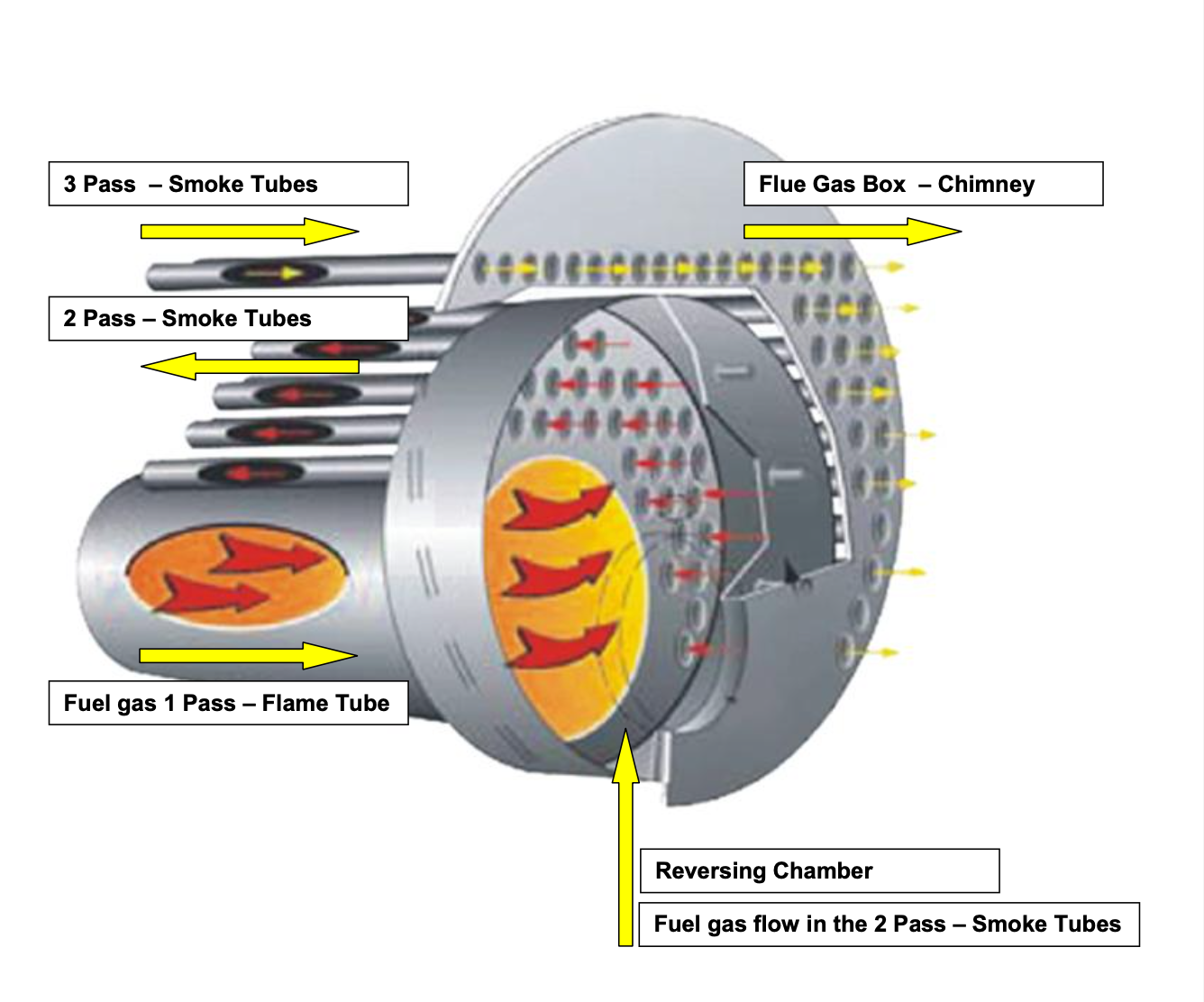

Applications of Super Duplex Seamless Tubes

The versatility of super duplex seamless tubes makes them indispensable across multiple sectors:

- Heat Exchangers in Petrochemical Plants

- Seawater-Cooled Condensers

- Geothermal Energy Systems

- Offshore Oil & Gas Facilities

- Power Plant Condensers and Coolers

By reducing welds and ensuring long, seamless lengths, operators achieve improved reliability, reduced leak risks, and extended operational cycles.

Conclusion – A Reliable Partner for Long-Length Tube Supply

This customer requirement demonstrates the growing demand for super duplex seamless tubes with long lengths and thin walls in heat exchanger applications. DLSS specializes in delivering precision-engineered duplex and super duplex tubes, backed by rigorous testing, traceability, and international project experience.

For inquiries, contact us at info@dlsspipe.com or visit www.dlsspipeline.com to learn how DLSS can support your next project with high-performance tubing solutions.