Introduction

Japan’s seawater desalination plants operate in highly corrosive environments due to the presence of chlorides and high salinity. TP904L stainless pipes from DLSS offer superior resistance to pitting and crevice corrosion, making them an ideal choice for JIS G3459 – Stainless Steel Pipes for Corrosion Resistance compliance in marine applications.

1. Why TP904L for Desalination(海水淡水化にTP904Lが選ばれる理由)

- High Nickel Content (25%) – enhances chloride stress corrosion resistance

- Copper Addition – improves resistance to sulphuric acid and seawater attack

- Low Carbon Design – prevents carbide precipitation during welding

2. JIS & ASTM Dual Compliance(JISとASTMの両方に準拠)

DLSS supplies JIS G3459 TP904L pipes with:

- ASTM A312 dual certification for global projects

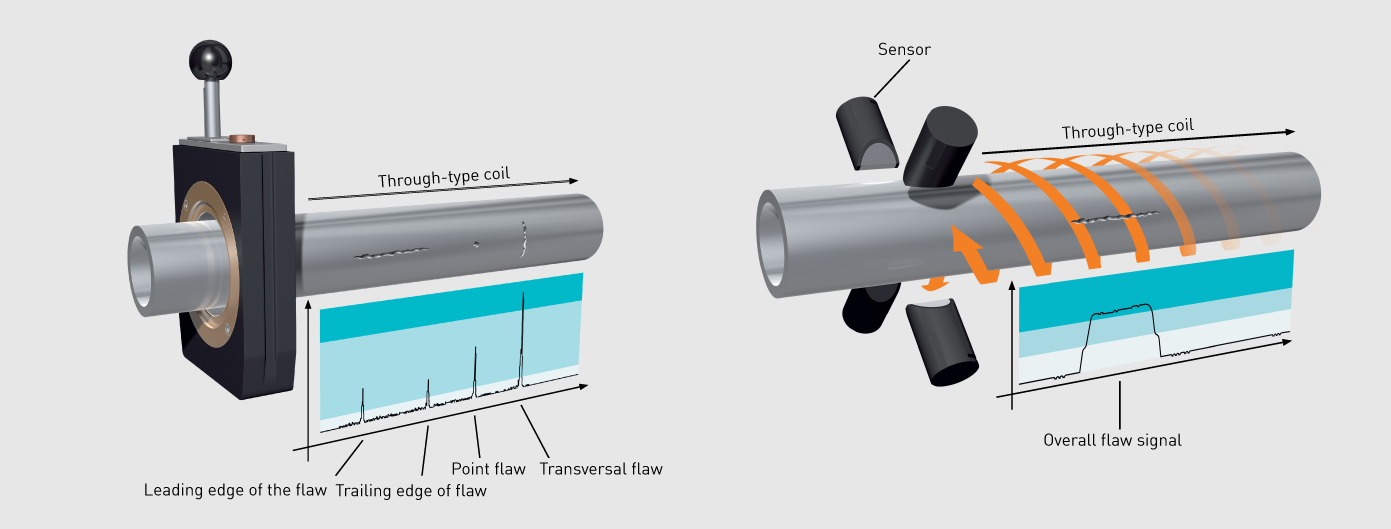

- 100% hydrostatic and eddy current testing

- Complete Mill Test Certificates (MTC) with corrosion test results

3. Applications in Japanese Desalination Plants(日本の淡水化プラントでの用途)

- Seawater intake pipelines

- High-pressure brine lines

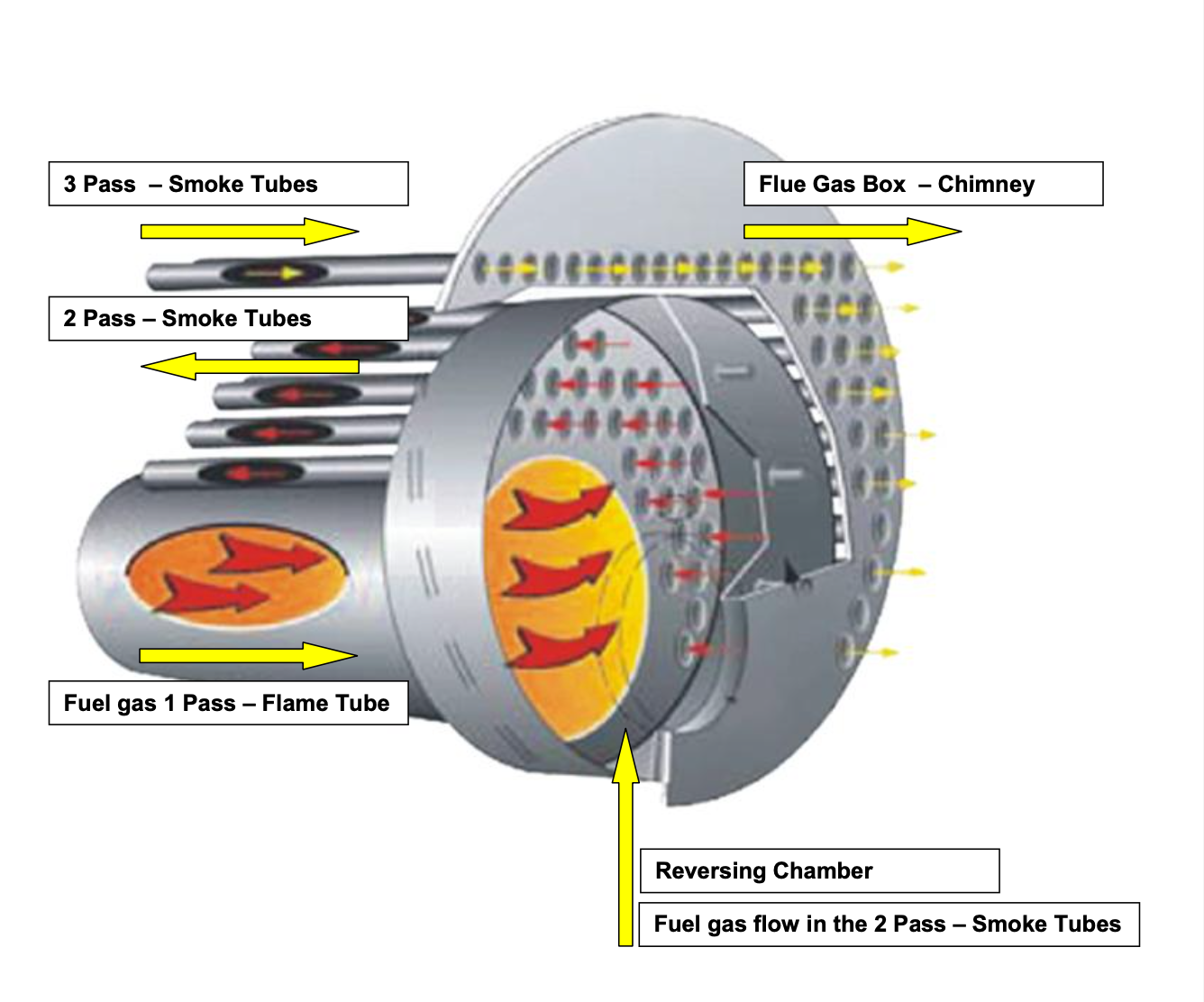

- Heat exchanger piping systems

- Reverse osmosis (RO) frame structures

4. Packaging for Marine Shipment(海上輸送用の梱包)

- Seaworthy export packaging

- Plastic end caps + moisture-proof wrapping

- Wooden crates for long-distance stability

5. Why Japanese Buyers Choose DLSS(日本バイヤーがDLSSを選ぶ理由)

- Proven track record in Japanese marine projects

- Ability to customize wall thickness & length

- Over 30 years of stainless pipe manufacturing expertise

FAQ(よくある質問)

Q1: Which JIS standard covers TP904L pipes for seawater applications?

A1: JIS G3459 is the main standard, with optional ASTM A312 dual certification.

Q2: How does TP904L compare to 316L in seawater corrosion resistance?

A2: TP904L performs significantly better in chloride-rich environments due to its high nickel and copper content.

Q3: Can DLSS provide TP904L with special surface finishes for desalination?

A3: Yes, we can provide pickled, polished, or passivated surfaces to enhance corrosion resistance.

Q4: What sizes of TP904L pipes are commonly used in Japanese desalination plants?

A4: Typical sizes range from 25.4 mm to 508 mm OD, with wall thicknesses from 1.65 mm to 12.7 mm.

Q5: How long is the lead time for TP904L delivery to Japan?

A5: Generally 40–55 days from order confirmation, depending on production schedule.