1. Introduction – How to Improve Heat Exchanger Efficiency

How to improve heat exchanger efficiency is a key question for operators who want lower energy bills, stable output, and longer asset life. Whether you run a shell and tube heat exchanger, a plate heat exchanger, or an air-cooled design, optimizing heat transfer performance delivers a fast return on investment.

2. Why Heat Exchanger Efficiency Matters

A high-efficiency heat exchanger:

- Reduces operating costs by lowering energy use.

- Improves process stability and product quality.

- Extends service life by minimizing thermal stress.

- Reduces CO₂ emissions and environmental impact.

In competitive sectors—chemical processing, marine cooling, power generation—small gains in heat exchanger efficiency can deliver significant annual savings.

3. Key Factors Affecting Heat Transfer Performance

Overall Heat Transfer Coefficient (U-value)

The U-value describes how effectively heat passes through the exchanger. A higher U-value means better performance. Learn more about thermal conductivity.

Temperature Difference (ΔT)

A larger temperature gradient between fluids increases the driving force for heat transfer.

Flow Configuration

Counterflow designs typically preserve a higher mean ΔT than parallel flow.

Fouling and Scaling

Deposits act as an insulating layer, lowering efficiency and increasing pressure drop. Learn more about fouling.

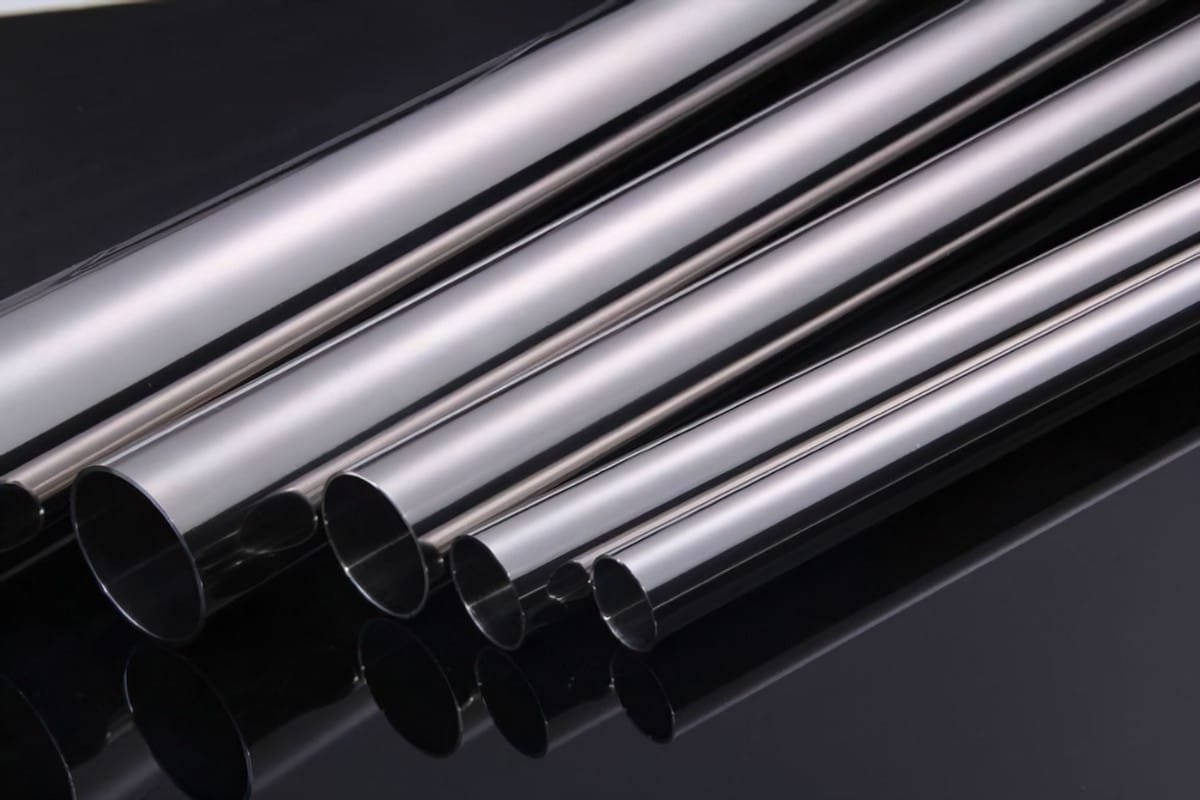

Material Selection

Corrosion-resistant alloys like duplex stainless steel or titanium improve performance stability in aggressive media.

4. 5 Proven Ways to Improve Heat Exchanger Efficiency

- Optimize Flow Rate and Turbulence – Increasing velocity within design limits enhances turbulence, improves heat transfer, and reduces fouling.

- Reduce Fouling Potential – To cut efficiency losses caused by deposits, follow these proven tips to prevent fouling in heat exchangers. For design-side gains, review shell and tube heat exchanger design considerations, and explore additional energy-saving strategies.

- Use High-Performance Materials – Grades like 316L, duplex 2205, and titanium provide strong corrosion resistance.

- Upgrade Design – Add surface area or use enhanced tube surfaces. Follow TEMA standards for shell and tube exchangers.

- Monitor and Maintain Regularly – Install sensors, schedule preventive cleaning, and follow ASME guidelines.

5. Real-World Example

A petrochemical plant replaced carbon steel tubes with duplex stainless steel 2205, increasing the heat transfer coefficient by 15% and extending cleaning intervals by 40%, saving over USD 50,000 annually.

6. Conclusion

Improving heat exchanger efficiency is about combining the right design, materials, and maintenance. By following these strategies, you can achieve lower costs and higher reliability. For more on fouling prevention, see 7 Effective Ways to Prevent Fouling in Heat Exchangers. For seawater applications, read Best Material for Seawater Heat Exchanger.

Contact DLSS

At DLSS, we manufacture high-quality stainless steel tubes for heat exchanger applications, ensuring optimal heat transfer, corrosion resistance, and long service life.

Email: info@dlsspipe.com

Website: www.dlsspipeline.com

Related Reading

- 7 Effective Ways to Prevent Fouling in Heat Exchangers

- Shell and Tube Heat Exchanger Design Considerations

- Energy-Saving Tips for Industrial Heat Exchangers