Introduction

Japan’s chemical industry demands high-performance stainless steel pipes capable of withstanding aggressive media and high temperatures. TP316L stainless pipes by DLSS meet JIS G3459 – Stainless Steel Pipes for Corrosion Resistance, ensuring durability, weldability, and excellent resistance to chloride-induced corrosion common in Japanese chemical processing plants.

1. Why TP316L for Japan’s Chemical Industry(日本化学産業でTP316Lが選ばれる理由)

- Low Carbon Content – minimizes carbide precipitation during welding

- High Molybdenum Content – superior pitting resistance in chloride environments

- JIS + ASTM Compliance – dual standard supply for global compatibility

2. JIS-Compliant Manufacturing(JIS規格準拠の製造)

DLSS produces JIS-certified stainless steel pipes in TP316L with:

- Strict dimensional tolerances

- Smooth inner surface finish (Ra ≤ 0.8 μm)

- 100% hydrostatic testing

3. Common Applications in Japanese Chemical Plants(日本化学プラントでの主な用途)

- Acid and alkali transfer lines

- High-temperature steam and condensate piping

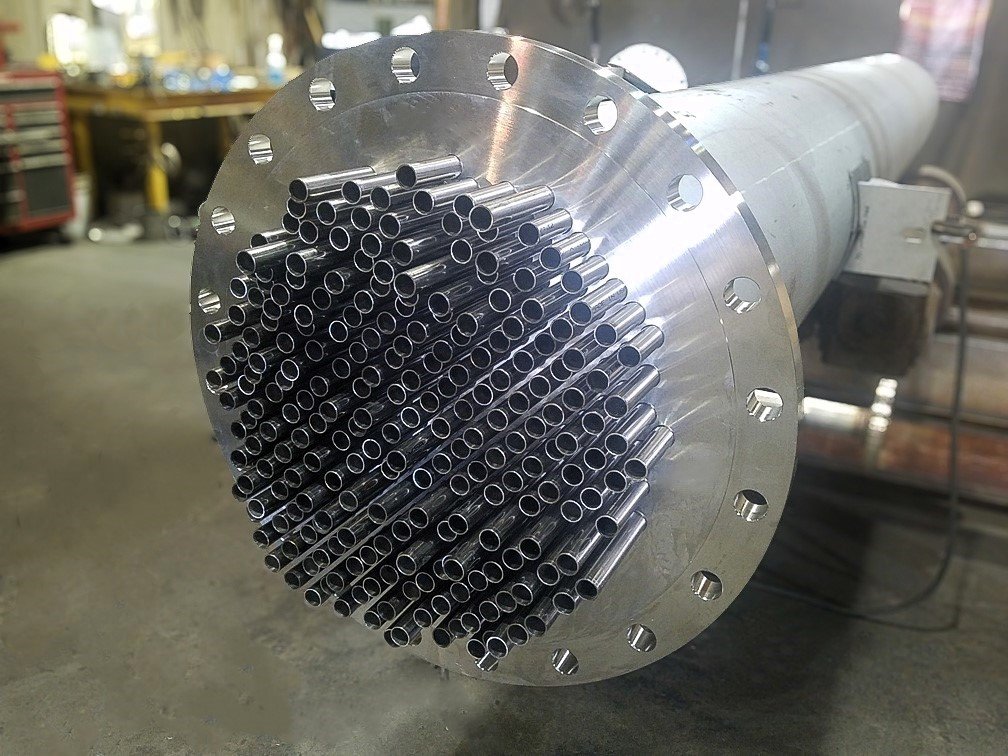

- Process heat exchangers

- Chloride-rich cooling systems

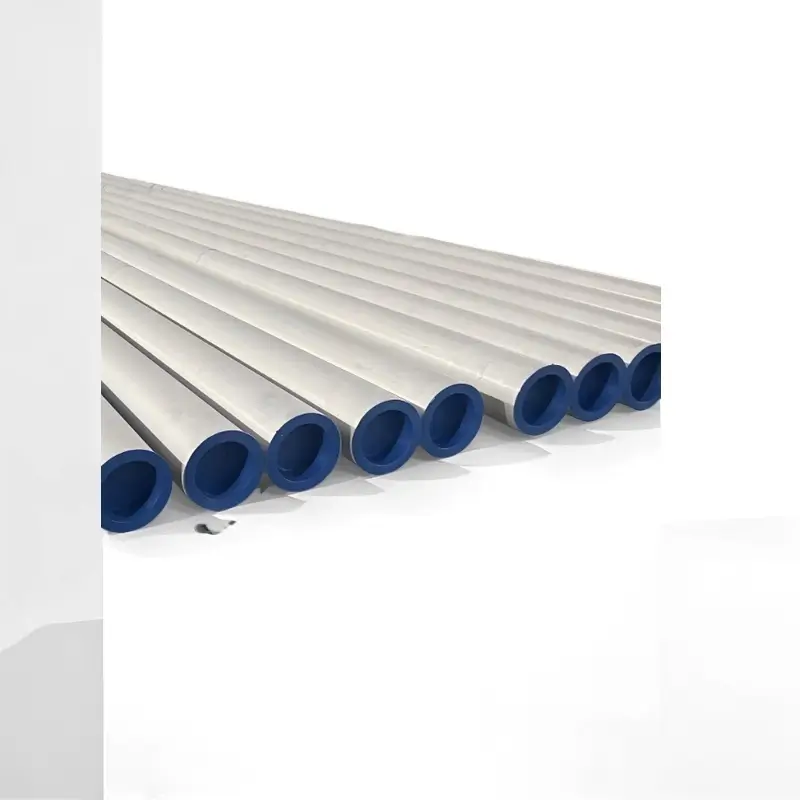

4. Packaging & Export for Japan(日本向け輸出梱包)

We ensure safe delivery with:

- Custom stainless tube packaging for export

- Plastic end caps to protect pipe ends

- Desiccants to avoid corrosion during sea freight

5. Advantages of Partnering with DLSS(DLSSと提携するメリット)

- Over 30 years of stainless steel manufacturing experience

- Expertise in heat exchanger tubes and custom solutions

- Reliable delivery to major Japanese ports including Tokyo, Osaka, and Nagoya

FAQ(よくある質問)

Q1: Which JIS standard covers TP316L stainless pipes in Japan?

A1: JIS G3459 – Stainless Steel Pipes for Corrosion Resistance is the main applicable standard.

Q2: What’s the difference between TP316 and TP316L?

A2: TP316L has lower carbon content, reducing the risk of sensitization during welding, making it ideal for chemical plant applications.

Q3: Can DLSS supply TP316L pipes with dual JIS and ASTM certification?

A3: Yes, we offer dual-certified materials for projects requiring both Japanese and international standards.

Q4: How are TP316L pipes tested before shipping to Japan?

A4: We perform hydrostatic tests, eddy current tests, and visual inspections to ensure compliance.

Q5: What is the lead time for TP316L stainless pipes to Japan?

A5: Standard production time is 35–45 days depending on size and order volume.