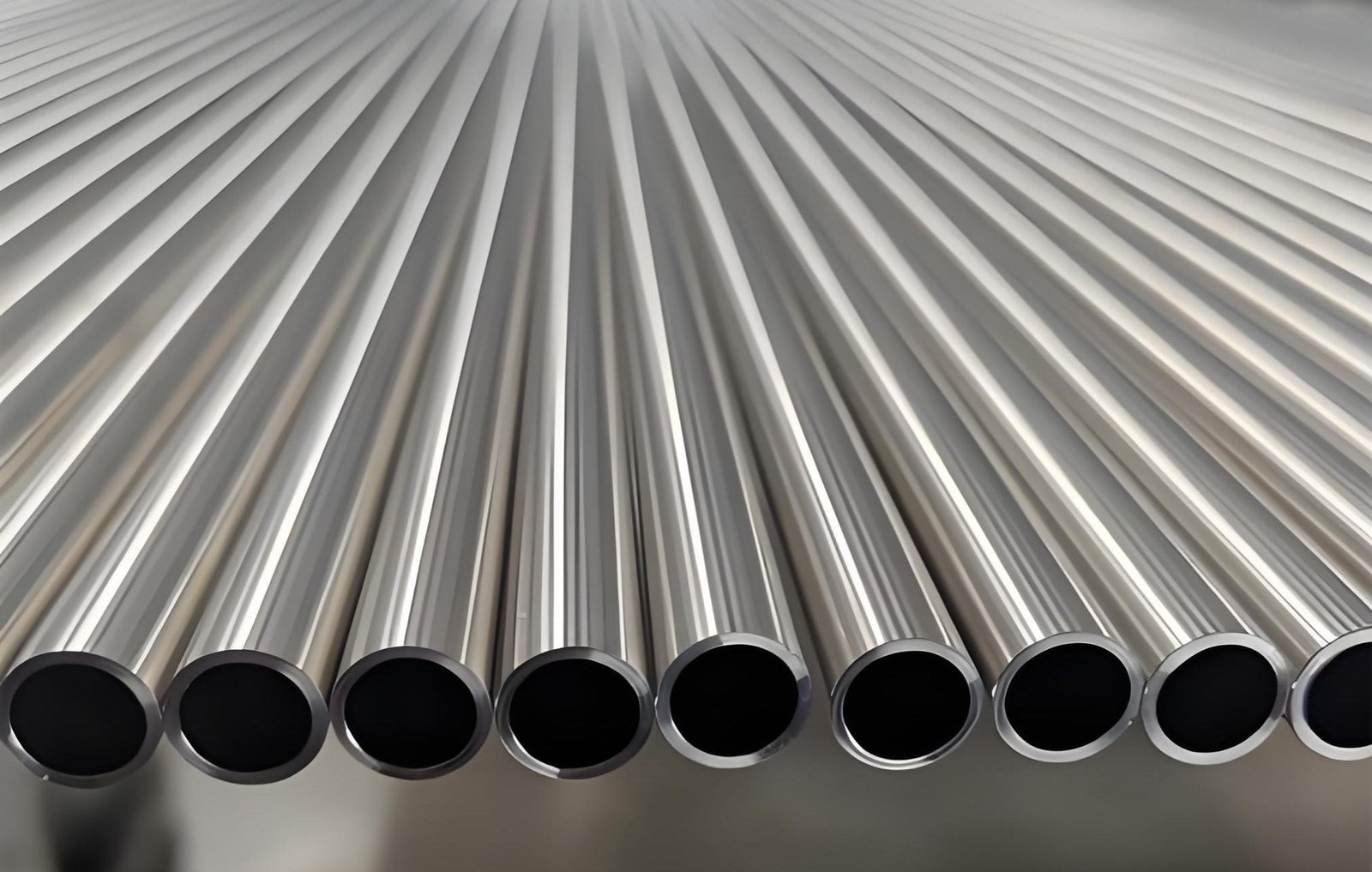

Product Overview: ASME SA213 TP316H Seamless Tube

ASME SA213 TP316H is a high-performance austenitic stainless steel seamless tube specifically designed for applications in high-temperature and highly corrosive environments. Widely used in critical industrial systems such as heat exchangers, boilers, condensers, and high-pressure fluid systems, this material meets the stringent standards set by ASTM A213 / ASME SA213.

This tube is specifically engineered to provide superior corrosion resistance, high tensile strength, and enhanced durability, making it the ideal choice for industries such as petrochemical, power generation, and chemical processing.

Key Specifications of ASME SA213 TP316H Seamless Tube

- Material Grade: TP316H (UNS S31609), a molybdenum-containing austenitic stainless steel that provides excellent resistance to high-temperature oxidation and corrosion.

- Outer Diameter: 19.05 mm (¾”)

- Wall Thickness: 2.0 mm

- Length: Available in lengths up to 6000 mm, providing flexibility for various installation requirements.

- Manufacturing Process: The tube is produced via the seamless method using hot-rolling or cold-drawing, ensuring precise dimensions and a smooth surface finish.

- Surface Finish Options: Available in 2B, BA, and bright finishes, catering to diverse industrial needs.

Chemical Composition and Mechanical Properties

ASME SA213 TP316H seamless tubes offer outstanding mechanical properties and chemical composition that ensure reliability in extreme operating conditions:

Chemical Composition (Typical TP316H):

- Carbon (C) ≤ 0.10%

- Chromium (Cr) 16-18%

- Nickel (Ni) 10-14%

- Molybdenum (Mo) 2-3%

- Manganese (Mn) 2.0% max

- Silicon (Si) 0.75% max

- Phosphorus (P) 0.045% max

- Sulfur (S) 0.030% max

The addition of molybdenum significantly enhances corrosion resistance, particularly in chloride environments, while also improving resistance to pitting and crevice corrosion.

Mechanical Properties:

- Tensile Strength: ≥ 515 MPa (75 ksi)

- Yield Strength: ≥ 205 MPa (30 ksi)

- Elongation: ≥ 40%

These properties make the TP316H tube suitable for use in environments that experience high-pressure conditions and extreme temperatures.

Ideal Applications for ASME SA213 TP316H Seamless Tube

ASME SA213 TP316H seamless tubes are extensively used in industries that require high performance, durability, and reliability in challenging environments:

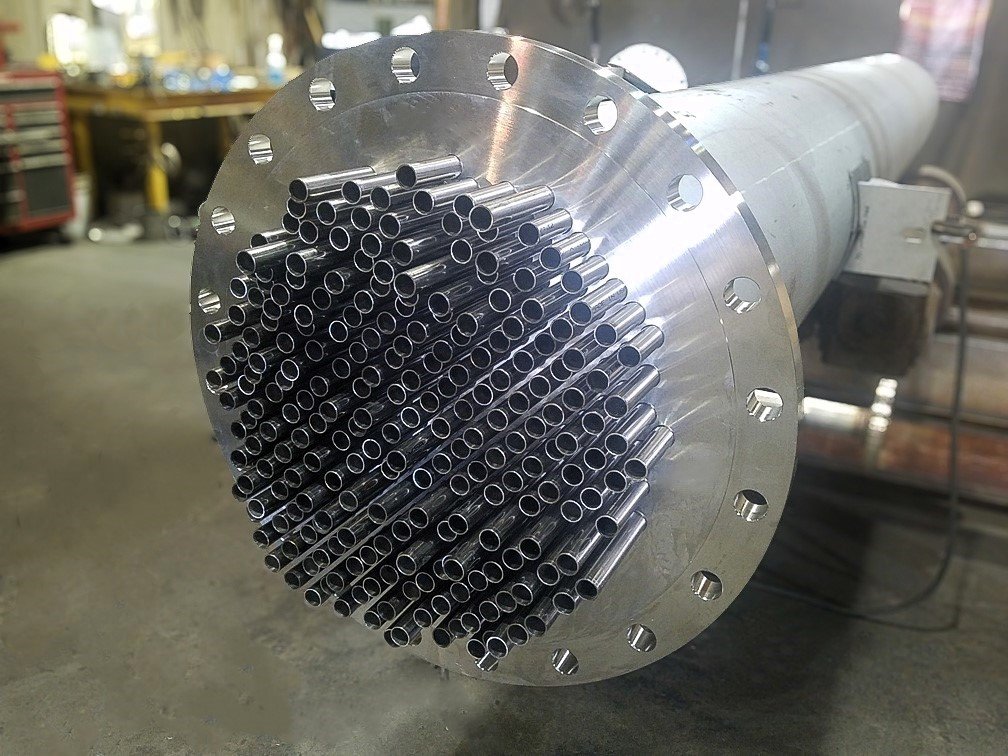

1. Heat Exchangers:

Used in heat exchangers where the fluid handling system operates at high pressures and temperatures. The TP316H tube’s excellent thermal conductivity and resistance to thermal cycling make it ideal for such applications.

2. Boilers and Steam Systems:

The tube is widely used in boiler systems where high-pressure steam needs to flow through pipes that can withstand constant exposure to heat and pressure without degrading or failing.

3. Chemical Processing:

In the chemical industry, TP316H is used for high-temperature processes that involve corrosive chemicals. The tube’s resistance to aggressive media, including acids and chloride compounds, makes it a preferred choice in this sector.

4. Power Generation:

The high resistance to oxidation and scaling, coupled with excellent mechanical strength, makes it ideal for the demanding conditions found in power generation plants.

5. Marine Environments:

Due to its resistance to pitting corrosion and chloride-induced stress corrosion cracking, TP316H is ideal for use in marine environments, particularly for offshore applications.

Manufacturing and Quality Control of ASME SA213 TP316H Seamless Tube

At DLSS, we ensure that every ASME SA213 TP316H seamless tube is manufactured to the highest standards, with meticulous attention to detail throughout the production process:

Manufacturing Process:

- Hot-Rolled: This is the most cost-effective manufacturing method for large-diameter pipes, ensuring faster production at a lower cost.

- Cold-Drawn: For applications requiring precise dimensions and enhanced surface finishes, cold-drawing provides improved dimensional accuracy.

- Seamless Construction: The seamless manufacturing process ensures there are no weak points, offering superior mechanical strength and reliability over welded alternatives.

Quality Control:

- Inspection: Each tube undergoes a thorough inspection process, including ultrasonic testing, eddy current testing, and visual inspection to ensure it meets the required standards.

- Testing: Comprehensive tests include chemical analysis, mechanical property testing (tensile, yield strength), and surface finish checks.

- Certification: All products come with a 3.1B certificate per EN 10204, providing assurance of compliance with the specified standards and material properties.

Key Purchasing Considerations for ASME SA213 TP316H Seamless Tube

When purchasing ASME SA213 TP316H seamless tubes, it is crucial to consider the following factors to ensure optimal performance and durability:

- Correct Specification: Confirm the exact dimensions (outer diameter, wall thickness, and length) required for your project.

- Material Certification: Ensure the tube comes with the necessary certification and test reports that validate its chemical composition and mechanical properties.

- Surface Finish: Choose the appropriate surface finish based on your application’s aesthetic or functional requirements (e.g., corrosion resistance, smoothness).

- Inspection and Testing: Verify the tube’s quality through rigorous inspections and testing procedures to ensure that it meets all necessary performance criteria.

- Logistics and Packaging: Ensure proper packaging (e.g., wooden crates with anti-corrosion treatment) to prevent damage during transport.

Summary: Why Choose ASME SA213 TP316H Seamless Tube?

ASME SA213 TP316H seamless tubes offer a combination of outstanding high-temperature resistance, excellent corrosion protection, and long-term reliability, making them the ideal solution for critical applications. Below are the top advantages:

| Advantage | Description |

|---|---|

| High-Temperature Performance | With added molybdenum, TP316H provides excellent resistance to high-temperature oxidation, ideal for steam and hot oil environments. |

| Superior Corrosion Resistance | TP316H is highly resistant to pitting, crevice corrosion, and chloride-induced stress corrosion cracking, making it perfect for chemical and marine environments. |

| Long-Term Reliability | The seamless design ensures no weak points, and strict quality controls ensure that every tube meets the highest standards. |

| Wide Applicability | Perfect for a wide range of industries including chemical processing, power generation, and marine applications. |

Conclusion: Ensure High Performance with ASME SA213 TP316H

ASME SA213 TP316H seamless tubes are a crucial component for high-demand industries that require materials capable of withstanding extreme pressures and temperatures. By ensuring precise material selection, stringent manufacturing processes, and thorough testing, DLSS guarantees that each tube meets the highest standards of performance and durability.

For further information on sizes, pricing, or to request a quote for your next project, please don’t hesitate to contact DLSS. Our team is ready to provide expert assistance and deliver the ideal solutions for your specific requirements.

Call to Action

Get a Free Consultation and Quote Now!

If you’re ready to elevate your industrial system with the high-performance ASME SA213 TP316H seamless tubes, contact DLSS today! Fill out our contact form or call us directly at [phone number] for immediate assistance. Our team of experts is standing by to provide tailored solutions and competitive pricing.

Subscribe for Updates

Stay updated on the latest products, industry news, and special offers by subscribing to our newsletter. Simply enter your email below, and we’ll keep you informed on all things related to seamless tube products and solutions.